Types of Aggregate and Sand Making Solutions

Shunzhi Machinery has various types of production lines. According to your production output and raw material requirements, we can customize corresponding production lines for you. There is always one that suits you.

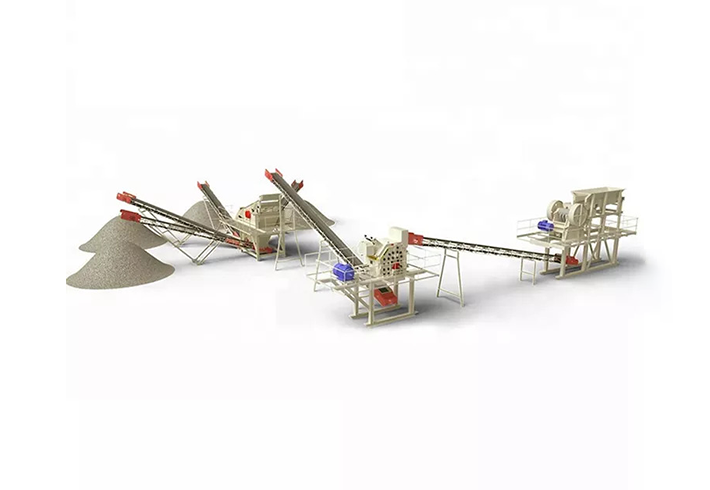

Stone Aggregate Production Line

A stone aggregate production line is a specialized system for producing construction sand and stone materials, characterized by high efficiency and environmental sustainability. Core equipment includes vibrating feeders, jaw crushers, hydraulic cone crushers, impact crushers, vertical shaft impact crushers (sand making machines), vibrating screens, belt conveyors, and centralized control systems.

Note1: Specific production line configurations can be customized.

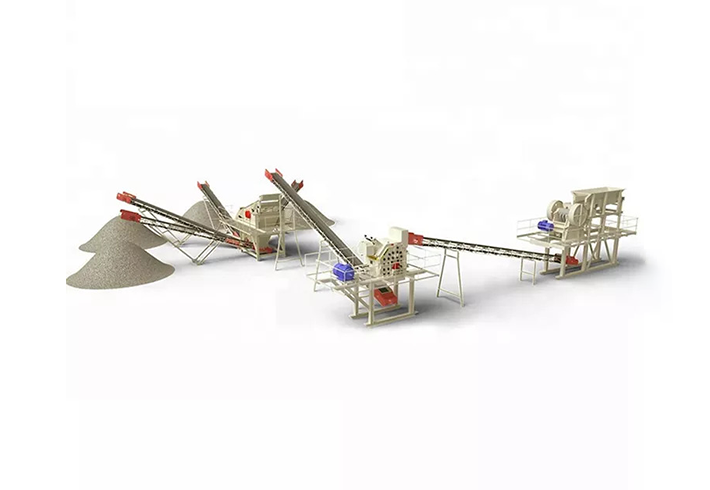

Stone Aggregate Production Line

A stone aggregate production line is a specialized system for producing construction sand and stone materials, characterized by high efficiency and environmental sustainability. Core equipment includes vibrating feeders, jaw crushers, hydraulic cone crushers, impact crushers, vertical shaft impact crushers (sand making machines), vibrating screens, belt conveyors, and centralized control systems.

Note: Specific production line configurations can be customized.

Mobile Stone Aggregate Production Line

The mobile stone aggregate production line can be equipped with tire-mounted, track-mounted, or modular mobile crushing stations. It eliminates traditional constraints such as site limitations, infrastructure dependencies, and logistics challenges by operating directly on-site, reducing material transportation costs.

Note: Specific production line configurations can be customized.

Mobile Stone Aggregate Production Line

The mobile stone aggregate production line can be equipped with tire-mounted, track-mounted, or modular mobile crushing stations. It eliminates traditional constraints such as site limitations, infrastructure dependencies, and logistics challenges by operating directly on-site, reducing material transportation costs.

Note: Specific production line configurations can be customized.

Sand Making Production Line

A sand making production line is a specialized process flow designed for manufacturing construction sand, primarily composed of various crushers, sand making machines, and sand washing equipment. Its core components include vibrating feeders, jaw crushers, impact crushers, cone crushers, sand making machines, vibrating screens, sand washers, and belt conveyors. The sand production line features high automation, large crushing ratio, high efficiency, and massive processing capacity. The final product exhibits a cubic shape with low needle-flake particle content, no internal cracks, and high compressive strength.

Note: The equipment configuration of the sand production line is mainly determined according to the customer’s specifications for the finished sand, the output and the type of stone.

Sand Making Production Line

A sand making production line is a specialized process flow designed for manufacturing construction sand, primarily composed of various crushers, sand making machines, and sand washing equipment. Its core components include vibrating feeders, jaw crushers, impact crushers, cone crushers, sand making machines, vibrating screens, sand washers, and belt conveyors. The sand production line features high automation, large crushing ratio, high efficiency, and massive processing capacity. The final product exhibits a cubic shape with low needle-flake particle content, no internal cracks, and high compressive strength.

Note: The equipment configuration of the sand production line is mainly determined according to the customer’s specifications for the finished sand, the output and the type of stone.

Mobile Sand Making Production Line

The mobile sand making production line integrates crushing, screening, and conveying functions into a single modular system. It can be flexibly configured based on production requirements and is designed for frequent relocation. Three mobility options are available: tire-mounted, track-mounted, and modular sled-mounted systems.

Note: The equipment configuration of the sand production line is mainly determined according to the customer’s specifications for the finished sand, the output and the type of stone.

Mobile Sand Making Production Line

The mobile sand making production line integrates crushing, screening, and conveying functions into a single modular system. It can be flexibly configured based on production requirements and is designed for frequent relocation. Three mobility options are available: tire-mounted, track-mounted, and modular sled-mounted systems.

Note: The equipment configuration of the sand production line is mainly determined according to the customer’s specifications for the finished sand, the output and the type of stone.

Aggregate and Sand Making Solutions

-

Granite Aggregates And Sand Production Solutions

-

Basalt Aggregates And Sand Production Solutions

-

Andesite Aggregates And Sand Production Solutions

-

Diabase Aggregates And Sand Production Solutions

-

Limestone Aggregates And Sand Production Solutions

-

River Pebbles Aggregates And Sand Production Solutions

Our Advantages

Shunzhi Machinery has adopted internationally advanced crushers, which have greatly improved the efficiency of the production equipment and reduced energy consumption, winning widespread recognition from customers.

Different

grades of sand are available depending on the size that

is needed. From

50t/h – 500t/h, you can customize any range of finished

product sizes

based on your requirements.

50-500t/h

Configuration

Our

machine’s routine inspections are simple and quick

because the wearing

parts use high-strength materials that last for a super

long periods in

service life spans compared with others.

-30%

maintenance costs

The high

production efficiency and automation degree of our

production line make

it an excellent choice for large-scale mining

operations, reducing a

large number of operating costs.

-46%

Operation costs

Our products have won widespread recognition from customers.

All

Application available

Shunzhi Aggregate/Sand Crushing Plant Price List

| Types | Price Range |

| Stone Aggregate Production Line | $15,000 – $200,000 |

| Mobile Stone Aggregate Production Line | $20,000 – $200,000 |

| Sand Making Production Line | $30,000 – $150,000 |

| Mobile Sand Making Production Line | $35,000 – $200,000 |

All the given prices are just referenced prices, the specific price is based on the required configuration. We can custom-make any type of sand-making machine or stone jaw crusher to meet your needs.

If you have questions about our available products, please do not hesitate and send us an email! We will show more detailed information such as videos for each device along with other helpful resources like screening machines available for purchase; no matter what decision fits best in terms of price range etc., we’re here ready to help guide you towards success.

Application Of Shunzhi Stone Aggregate And Sand Making Plants

Shunzhi sand production plant has a wide range of applications in the construction industry. From road building to foundation laying, this equipment is essential in the production of artificial sand and other aggregates. It is mainly used for producing high quality construction sand, which can be blended with gravel or asphalt for the construction of highways, bridges and other infrastructure projects.

Generally speaking, our sand crushing plants can be used in industries like:

Water conservancy and hydropower;

Construction of tunnels, highways and railways;

Real estate development, ports and airports;

Engineering projects;

Mining, metallurgy and chemical industries;

Cement, concrete processing industries.

If you are in the construction industry and need high quality sand machines for your projects, please contact us today to learn more about our Shunzhi sand making plant. We can provide you with the best equipment for your needs and help you get the most out of your construction.

Advantages of Stone Aggregate Production Line

The high degree of automation

Our stone aggregate production line has a high degree automation design to reduce operator, low running costs, and stable operation.

Uniform particle size

Our machine guarantees uniform particle size output, which greatly reduces the phenomenon of uneven fineness when using other sand making machines. It also consumes less energy during production.

High Efficient

The machine in our company is equipped with advanced production technology and has high production efficiency. It can produce a large number of high-quality artificial sands at one time, and the output is very high.

Cost Savings

Reduced Infrastructure Costs: Since it doesn't require the construction of a permanent production plant, costs related to building structures, power supply systems, and water supply systems for a fixed facility are avoided.

Advantages of Mobile Stone Aggregate Production Line

High Mobility and Flexibility

Quick Relocation: It can be easily moved from one construction site or mining area to another. This is especially beneficial for projects that require frequent changes in location, such as road construction projects that span long distances or small to medium-sized mining operations that need to shift to different ore bodies. For example, in mountainous road construction, the mobile production line can be transported to different sections of the roadbed construction site as needed.

Adaptability to Different Terrains: The tire-mounted or track-mounted types can adapt to various terrains, including rough and uneven ground. Track-mounted models are particularly suitable for soft or hilly terrains where traditional fixed production lines would be difficult to install.

Reduced Installation and Setup Time

No Need for Extensive Foundation Work: Unlike fixed aggregate production lines that require a large amount of time and cost to build a solid foundation, the mobile production line can be quickly set up on-site. It can be put into operation in a relatively short time, saving both time and construction costs.

Integrated Modules: The production line is designed as integrated modules, which means that the different components such as the crusher, screen, and conveyor are pre-assembled. This simplifies the installation process and reduces the complexity of on-site assembly.

Adjustable Production Configuration: It can be configured in different ways according to the specific requirements of the project, such as single-stage or multi-stage crushing, and different screening arrangements. This allows for greater flexibility in meeting the production needs of different aggregate specifications.

Ease of Maintenance

Modular Design for Easy Access: The modular design of the mobile production line makes it easier to access individual components for maintenance and repair. This simplifies the maintenance process and reduces the time required for troubleshooting and component replacement. For example, if a part of the crusher needs to be repaired or replaced, the modular structure allows for quick disassembly and reassembly.

Centralized Control System: Many mobile production lines are equipped with a centralized control system, which enables operators to monitor and control the entire production process. This helps in early detection of potential problems and timely maintenance, ensuring the continuous and stable operation of the production line.

Advantages of Sand Making Production Line

Simple production process

Our sand making machine has a simple production process, which can be roughly divided into three steps: material feeding, crushing, and sand making. The whole sand making process is simple, reasonable, and efficient, and it can be put into production quickly after being put into production.

Low failure rate

The sand making machine has a low failure rate and high output. It is generally used for the production of glass, ceramics, refractories, cement, and other products.

Intelligent control

With an intelligent control system, it can automatically adjust the speed according to the material characteristics and feed amount. And it is easy to operate and maintain, which greatly reduces maintenance costs.

Efficient Production

Seamless Process Integration: The mobile production line integrates feeding, crushing, screening, and conveying processes. The equipment is coordinated in a way that ensures a smooth flow of materials, minimizing downtime and increasing overall production efficiency. For example, the vibration feeder can evenly supply materials to the crusher, and the conveyor can quickly transport the crushed materials to the screening equipment.

Environmental Benefits

Dust and Noise Control: Equipped with advanced dust suppression systems (e.g., sprayers, filters) to meet stringent environmental regulations.

Advantages of Mobile Sand Making Production Line

Enhanced Mobility and Flexibility

Quick Relocation:Designed with integrated chassis and compact structures, these production lines can be rapidly deployed to various job sites (e.g., mining areas, construction waste sites) without requiring extensive transportation of raw materials, significantly reducing logistical costs.

Adaptability to Terrain: High-mobility chassis enable stable operation on rough terrain, while compact layouts allow efficient use of limited workspaces.

Configurable Workflows: Supports modular combinations with crushers, screens, and conveyors to adapt to diverse material types and output requirements.

Cost Efficiency

Reduced Infrastructure Investment: Eliminates the need for fixed foundations or long-term site preparation, lowering initial capital expenditure.

Lower Operational Costs: On-site processing minimizes material transportation expenses and reduces environmental pollution from hauling.

High Operational Efficiency

Integrated Automation: PLC intelligent control systems enable remote monitoring and adjustments, improving production accuracy and reducing manual intervention.

Direct Processing Capability: Combines crushing, sand-making, and screening in a single unit, streamlining workflows and ensuring continuous production.

Sustainable Material Recycling: Ideal for repurposing construction waste and natural stones into reusable sand aggregates, promoting circular economy practices.

Versatile Application

Material Diversity: Handles hard rocks (e.g., granite, basalt), river pebbles, and construction debris with adjustable output sizes (e.g., 0–5 mm, 0–10 mm).

Multi-Scenario Use: Suitable for temporary projects, remote locations, or urban areas with limited space.

Reduced Maintenance Complexity

Durable Components: Utilizes wear-resistant materials for critical parts (e.g., impact plates, liners) to extend service life and minimize downtime.

Simplified Maintenance: Modular designs facilitate easy access to components for repairs or replacements.

Enquiry

Enquiry Online Chat

Online Chat