SWM Wheel-mounted Mobile Crushing & Screening Station

SWM Wheel-mounted Mobile Crushing & Screening Station

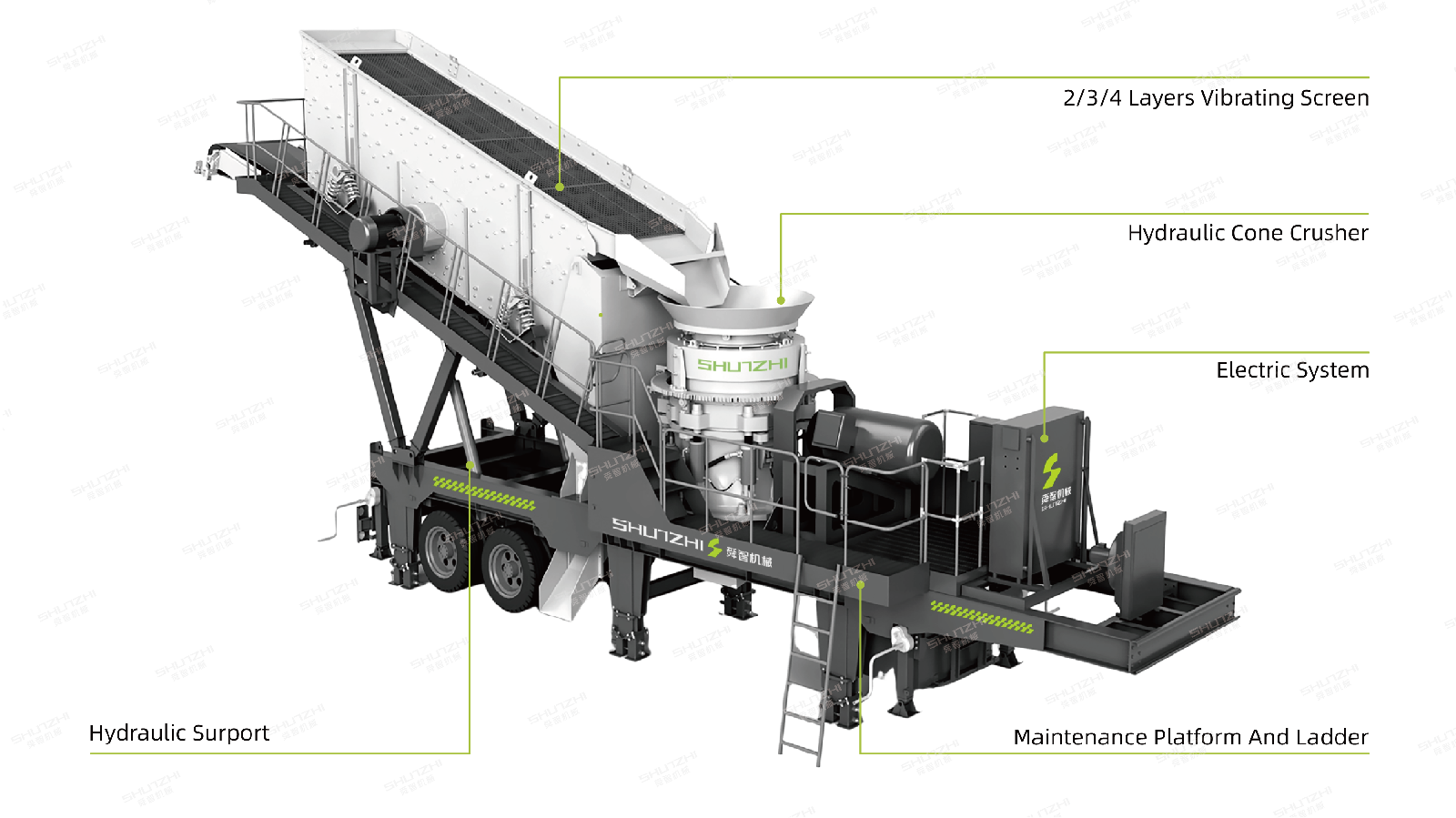

SWM crushing and screening mobile crushing station adopts integrated, modular design, simple frame,crushing and screening one-in-one, convenient support system makes it convenient for customers to quickly transfer construction.

Advantages Of SWM Wheel-mounted Mobile Crushing & Screening Station

Advantages Of SWM Wheel-mounted Mobile Crushing & Screening Station

The jaw crusher + impact crusher four-combination mobile crushing station has been widely used in many industries such as mining, building materials, and solid waste treatment due to its advantages such as efficient crushing, flexible adaptability, energy saving, and economy, intelligent automation, and environmental protection and safety.

High-strength frame design, strong impact resistance compact size, frame can be loaded into in a container -Unique boots design, no additional concrete base foundation, time-saving and labor saving

By combining the cone crusher, the impact crusher and sand maker, optimizing equipment selection, adjusting crushing parameters, strengthening equipment maintenance, and adopting new technologies, the crushing power can be significantly increased, production efficiency can be improved, and production costs can be reduced.

Impact crusher, cone crusher and VSI crushers can be interchanged to meet the production needs of different materials.

The jaw crusher and the impact crusher each bear different operating loads during the crushing process, which helps to reduce overall energy consumption. Compared with traditional fixed crushing stations, the four-combination mobile crushing station reduces infrastructure construction investment, such as foundations and Station buildings.

Application Of SWM Wheel-mounted Mobile Crushing & Screening Station

Application Of SWM Wheel-mounted Mobile Crushing & Screening Station

The feeder, jaw crusher, impact crusher, and vibrating screen are integrated into a frame to form a closed crushing production line, which is efficient and flexible. It is suitable for small-capacity stone-crushing equipment production lines and can independently meet the production needs of customers.

What Is The Working Principle Of SWM Wheel-mounted Mobile Crushing & Screening Station

What Is The Working Principle Of SWM Wheel-mounted Mobile Crushing & Screening Station

Reduce the operating load of the impact crusher: The coarse crushing effect of the jaw

crusher breaks large pieces of material into smaller pieces, reducing the operating load

of the impact crusher, thereby increasing the overall crushing power.

Optimize particle size distribution: The particle size distribution of the crushed

product of the jaw crusher is relatively wide, while the impact crusher can further

adjust and optimize the particle size distribution to ensure that the product particle

size meets the requirements.

Improve overall crushing efficiency: The combined use can give full play to the

advantages of the two crushers, improve the overall crushing efficiency, and shorten the

crushing time.

|

Device/Model |

SWP430S |

SWP440S |

SWH300S |

SWF1213S |

SWF1315S |

SWV8522 |

SWV9532 |

|

Crusher |

CH430 |

CH440 |

HP300 |

SP1213 |

SP1315 |

VSI8522N |

VSI9532N |

|

Screening Machine |

3YK1860 |

3YK2160 |

3YK1860 |

3YK1860 |

3YK2160 |

3YK1860 |

3YK2160 |

|

Belt Conveyor Under Screen |

B1000 |

B1200 |

B1200 |

B1000 |

B1200 |

B1000 |

B1200 |

|

Machine Power(KW) |

202 |

273.5 |

290 |

240 |

355 |

276 |

376.2 |

|

Generator Set Power(KW) |

330 |

550 |

550 |

500 |

950 |

400 |

550 |

Attention: The generator is an external generator set, and customers need to purchase it themselves or Shunzhi can provide a quotation.The standard quotation does not include the generator. For more models, please consult Shunzhi.