SWH Wheel-mounted Mobile Cone Crushing Station

SWH Wheel-mounted Mobile Cone Crushing Station

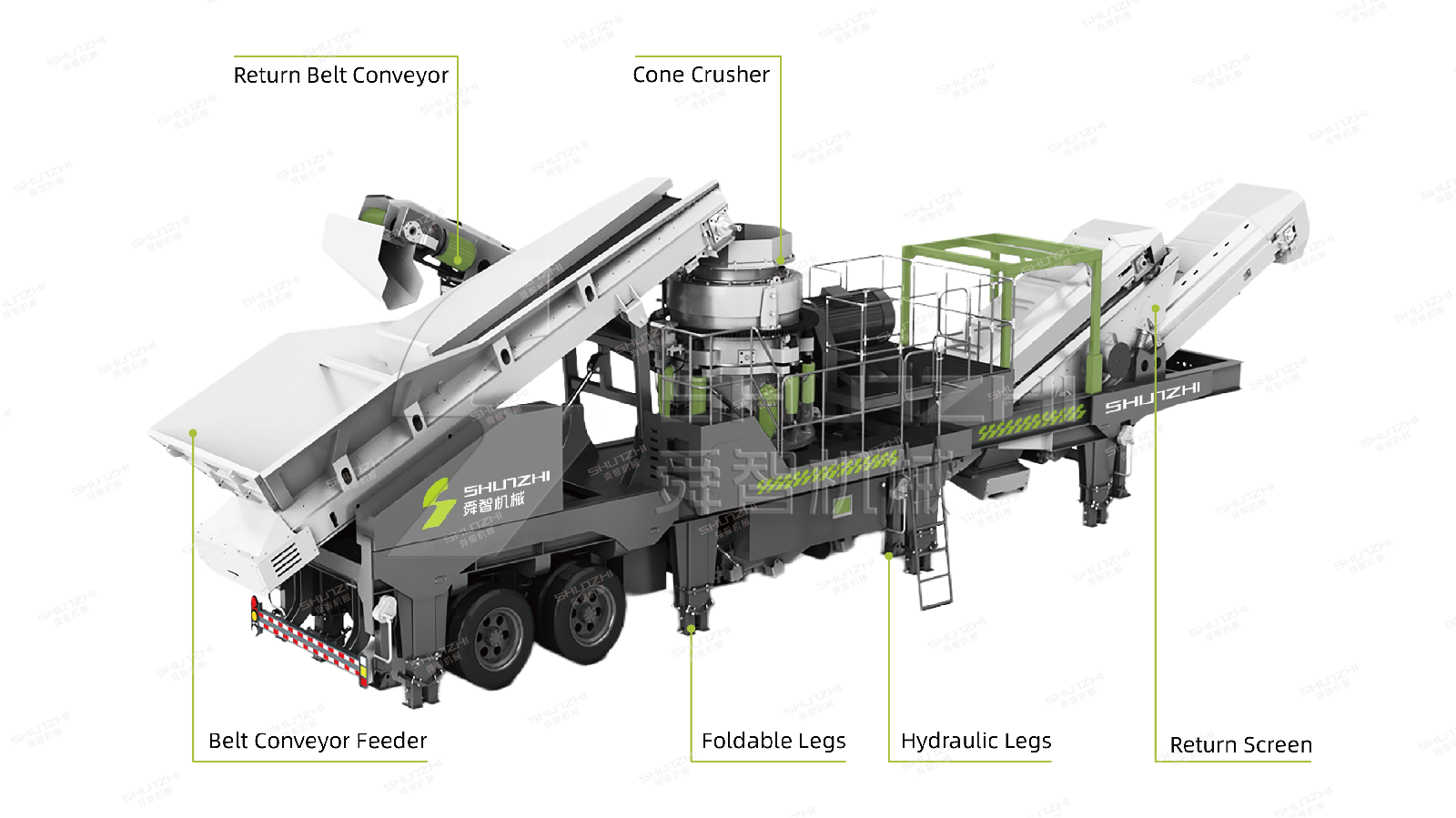

SWH medium crushing cone tire type mobile crushing station adopts integration,modular design, simple frame, all equipment is vehicle-mounted,convenient support system makes it convenient for customers to quickly transfer construction.

Advantages Of SWH Wheel-mounted Mobile Cone Crushing Station

Advantages Of SWH Wheel-mounted Mobile Cone Crushing Station

Mobile cone crushing plants have broad application prospects in the field of crushing operations due to their high flexibility, efficient crushing capacity, wide applicability, energy saving and environmental protection, intelligent control, and high cost-effectiveness.

Mobile cone crusher, also known as a mobile cone crushing station or tire-type mobile

cone crushing station, is an efficient and flexible crushing equipment.

Mobile cone crusher is mainly composed of high-performance cone crushers, vibrating

screens,

belt conveyors, etc. It adopts a vehicle-mounted installation method, which is

convenient for transportation and rapid deployment on-site.

Mobile cone crushing plant can operate independently as a single unit, or it can be

flexibly composed of system configuration units for joint operation.

Cone crusher adopts advanced crushing principles and design, which can realize efficient

and continuous crushing operation, has a large production capacity, and meets

large-scale production needs.

Processing sand and gravel aggregates with high hardness and fine particle size; often used for artificial sand making of river pebbles, mountain stones (limestone, granite, basalt, etc.), ore tailings, and stone chips.

The maximum feed size that the mobile cone crusher can handle is up to 240mm, the finished product particle size can be controlled between 18~40mm, and the output of a single machine ranges from 50~300t/h.

Application Of SWH Wheel-mounted Mobile Cone Crushing Station

Application Of SWH Wheel-mounted Mobile Cone Crushing Station

Mining:In mining, the mobile cone crushing station can move with the mining

progress of the mine to crush the ore. This equipment can handle ores of various hardnesses and

has a stable crushing effect, which helps to improve the mining efficiency and output of the

mine.

Construction waste recycling:For the processing and recycling of construction

waste, mobile cone crushing stations can also play an important role. It can crush construction

waste and convert it into reusable aggregates, thereby realizing resource recycling and reducing

the impact on the environment.

What Is The Working Principle Of SWH Wheel-mounted Mobile Cone Crushing Station

What Is The Working Principle Of SWH Wheel-mounted Mobile Cone Crushing Station

The mobile cone crusher relies on the power provided by external electricity or an onboard

generator to drive the main engine and auxiliary equipment motors. The motor drives the

eccentric sleeve to rotate through the transmission device. The movable cone rotates and

swings under the force of the eccentric sleeve. This rotation and swing is the key to the

crushing process.

The rotation and swing of the movable cone of the cone crusher drive the crushing wall to

squeeze and grind the material between the crushing wall and the mortar wall. According to

the lamination theory, when the material is subjected to forces in multiple directions, it

will be crushed and polished along its own texture, and then form stable stone particles.

The crushed stones are returned to the vibrating screen of the mobile cone crusher through

the belt conveyor for screening. The screened stones are transported to the finished product

area strictly according to different specifications, and the large-sized stones are returned

to the cone crusher for re-crushing, and then the screening is repeated until the finished

product specifications are reached.

|

Device/Model |

SWP430 |

SWH300 |

SWP430RS |

SWH300RS |

SWH500RS |

|

Feeding Machine |

B1000-7m |

B1000-7m |

B1000-7m |

B1000-7m |

B1200-7m |

|

Crusher |

CH430 |

HP300 |

CH430 |

HP300 |

HP500 |

|

Screening Machine |

-- |

-- |

SX1536 |

SX1536 |

SX1536 |

|

Main Belt Conveyor |

B1000 |

B1000 |

B1000 |

B1000 |

B1200 |

|

Machine Power(KW) |

230.5 |

284.4 |

264.9 |

325.9 |

515.4 |

|

Generator Set Power(KW) |

400 |

550 |

400 |

550 |

1000 |

Attention: The generator is an external generator set, and customers need to purchase it themselves or Shunzhi can provide a quotation.The standard quotation does not include the generator. For more models, please consult Shunzhi.