STS Track-mounted Portable Vibrating Screening Station

STS Track-mounted Portable Vibrating Screening Station

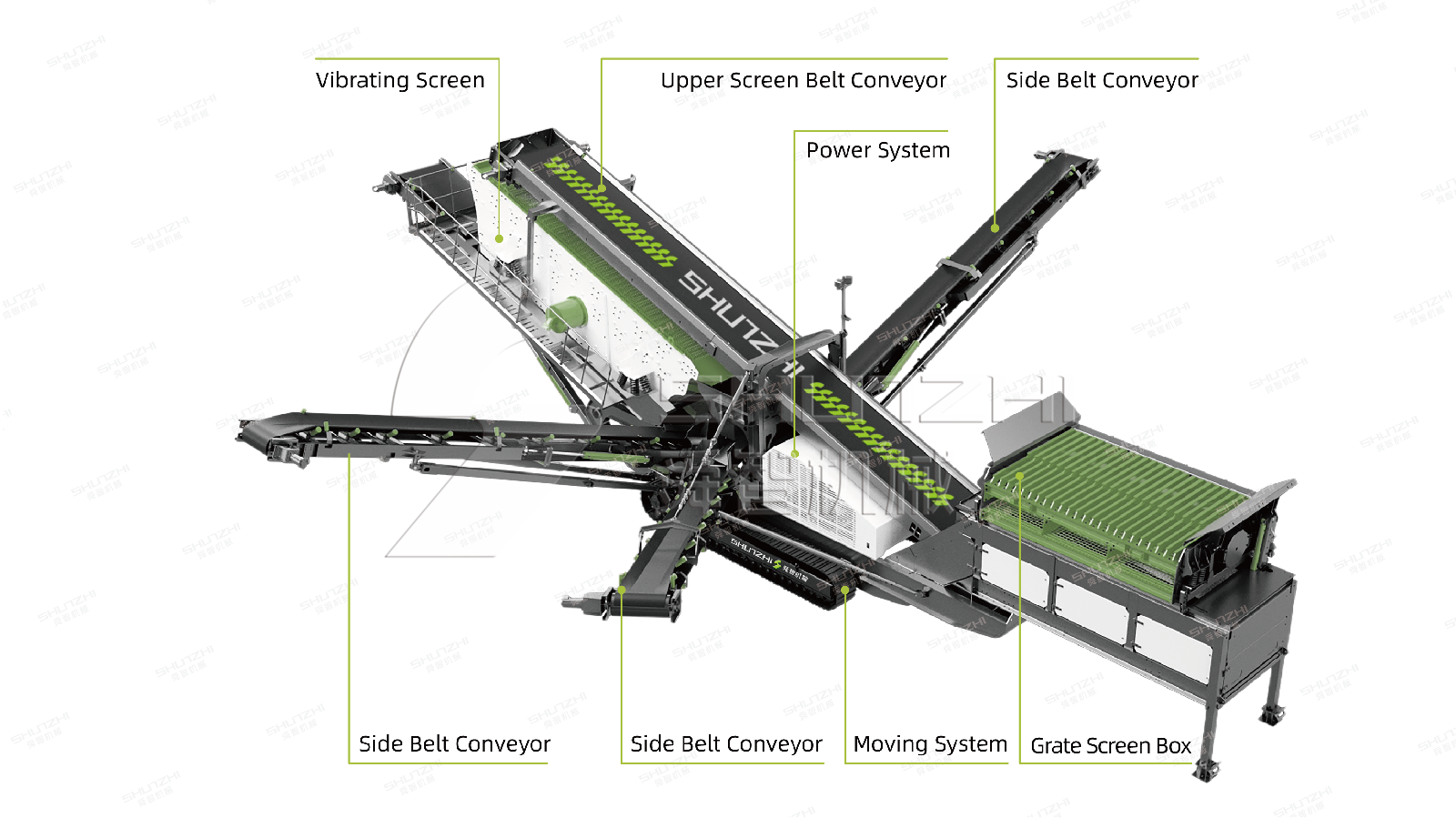

STS series crawler screening mobile station has an independent power unit and can walk independently. It can be combined with other crushing stations to form a production system. It is designed with a grate feed box and can work independently for pre-screening and other working conditions.

Advantages Of STS Track-mounted Portable Vibrating Screening Station

Advantages Of STS Track-mounted Portable Vibrating Screening Station

Track-mounted Mobile Vibrating Screen, also known as a crawler mobile screening plant, is a high-performance mobile crushing and screening equipment.

Crawler screening stations can screen and grade various loose minerals and rocks, such as diabase, andesite, ore tailings, limestone, granite, basalt, etc. At the same time, it can also screen construction waste, separate reusable materials, and realize the recycling of resources.

The crawler crushing station consists of a mobile crushing and screening system, including a primary crushing station, a secondary crushing and screening station, a conveyor, etc. Each level of crushing station is an independent working unit, which can perform its different duties. In addition, it is usually equipped with key components such as receiving hoppers, screening mechanisms, silos, and control systems.

Application Of STS Track-mounted Portable Vibrating Screening Station

Application Of STS Track-mounted Portable Vibrating Screening Station

Track-mounted Mobile Vibrating Screen are widely used in quarries, mines, construction demolition debris processing, surface soil processing, material recycling, gravel screening, coal and aggregate screening, etc. At the same time, it can also be used for the classification of materials in industries such as mineral processing, power, and chemical industry.

What Is The Working Principle Of STS Track-mounted Portable Vibrating Screening Station

What Is The Working Principle Of STS Track-mounted Portable Vibrating Screening Station

The Track-mounted Mobile Vibrating Screen is driven by its own power system to crush and screen the materials on site. During the screening process, the materials roll continuously in an elliptical shape on the vibrating screen. Through continuous flipping and loosening, the fine particles have the opportunity to move to the bottom of the material layer and be discharged through the screen holes, while the materials with a particle size larger than the screen holes can jump out of the screen and enter the finished material conveyor.

|

Device/Model |

STS1860-3 |

STS2160-3 |

STB1860-3 |

|

Feeding Department |

|||

|

Feed hopper volume(m³) |

3 |

3 |

8 |

|

Feed hopper form |

Ordinary style |

Ordinary style |

Rician style |

|

Screening machine |

|||

|

Device/Model |

3YK1860 |

3YK2160 |

3YK1860 |

|

Number of layers |

3 |

3 |

3 |

|

Belt Conveyor |

|||

|

Upper screen belt conveyor |

B1000 |

B1000 |

B1000 |

|

Belt Conveyor Under Screen |

B1000 |

B1000 |

B1000 |

|

Side Outlet Belt Conveyor |

650-6m |

650-6m |

650-6m |

|

Side Outlet Two-Belt Conveyor |

650-7.5m |

650-7.5m |

650-7.5m |

|

Side Outlet Three-Belt Conveyor |

650-7.5m |

650-7.5m |

650-7.5m |

Power |

|

Machine Power(KW) |

74.5 |

84.5 |

74.5 |

|

Power System(KW) |

Cummins 120 |

Cummins 120 |

Cummins 120 |

Attention: The generator is an external generator set, and customers need to purchase it themselves or Shunzhi can provide a quotation.The standard quotation does not include the generator. For more models, please consult Shunzhi.