STH Track-mounted Portable Cone Crushing Station

STH Track-mounted Portable Cone Crushing Station

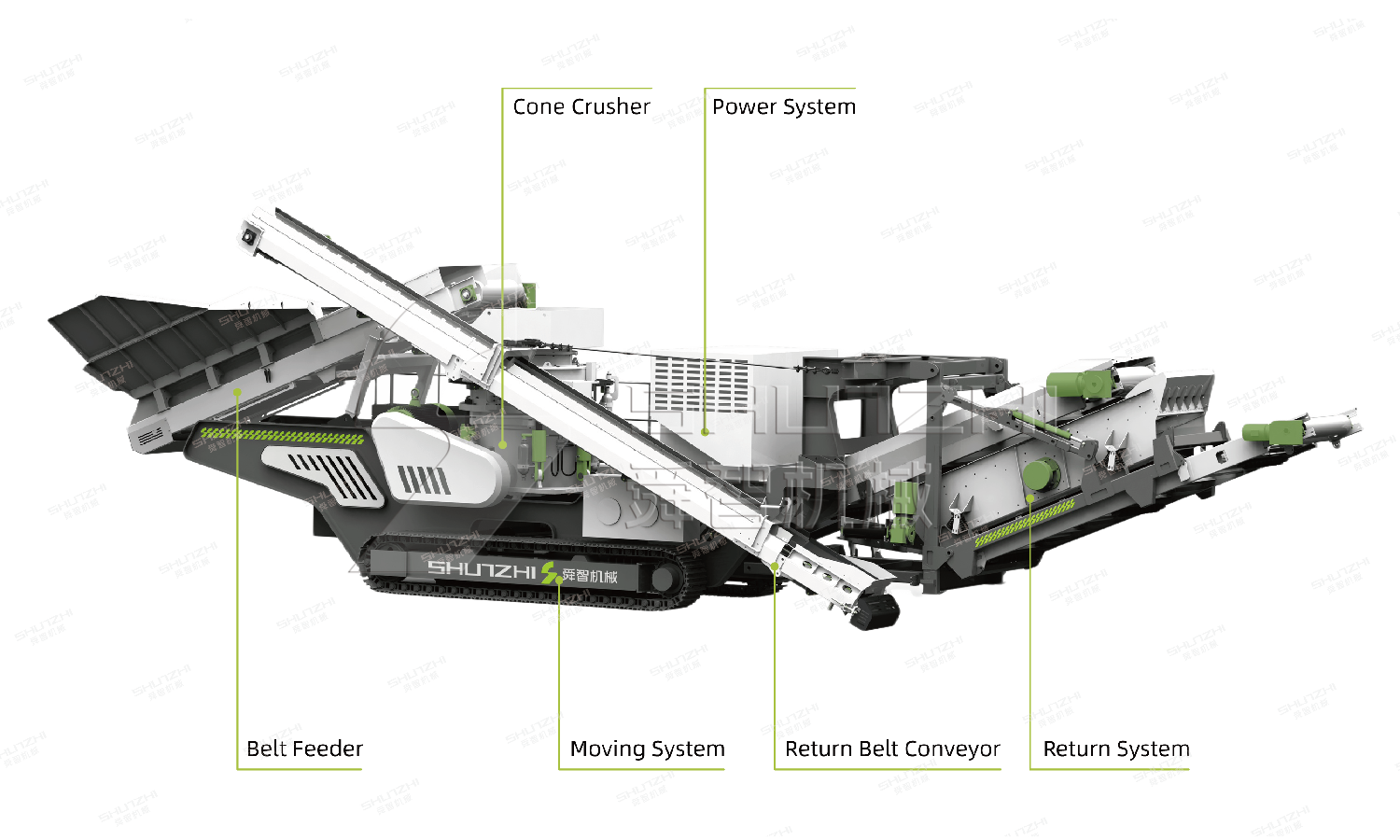

STH series crawler cone crusher has an independent power unit and can walk independently.It has a complete feeding, crushing, screening, and returning system.It can work alone or can be combined with jaw breaking,screening and other equipment to form a production line to meet different customer requirements.

Advantages Of STH Track-mounted Portable Cone Crushing Station

Advantages Of STH Track-mounted Portable Cone Crushing Station

Track-mounted Portable Cone Crusher, also known as crawler Portable cone crusher, is a large-scale combined Portable crushing equipment that integrates receiving, crushing, conveying, and other process equipment.

Crawler hydraulic cone Portable crusher is a Portable crushing and screening equipment that integrates cone crusher, feeder, vibrating screening equipment and crawler walking device. It has good crushing performance for rock crushing, aggregate production and open-pit mining.

Crawler hydraulic cone Portable crusher is widely used in various materials, such as river pebbles, limestone, basalt, shale, diabase, etc., especially suitable for material processing and fluid stone processing that requires relocation operations.

Application Of STH Track-mounted Portable Cone Crushing Station

Application Of STH Track-mounted Portable Cone Crushing Station

Track-mounted Portable Cone Crusher is a kind of efficient, flexible, and adaptable crushing equipment, that is widely used in mining, construction, the chemical industry, and road construction.

What Is The Working Principle Of STH Track-mounted Portable Cone Crushing Station

What Is The Working Principle Of STH Track-mounted Portable Cone Crushing Station

The working principle of the crawler cone crusher is mainly based on lamination crushing.

When the material enters the crushing chamber, the moving cone is driven by the motor to

rotate, driving the material to be crushed between the fixed cone and the moving cone.

The material is first impacted by the moving cone, and then squeezed between the moving cone

and the fixed cone, and crushed by lamination. By adjusting the gap between the moving cone

and the fixed cone, the particle size of the output material can be controlled.

|

Device/Model |

STP430RS |

STH300RS |

STH400RS |

STH300RS(E) |

|

|

Feeding Department |

|||||

|

Bin Volume(m³) |

5 |

6.5 |

6.5 |

6.5 |

|

|

Feeder Model |

B1000 |

B1200 |

B1200 |

B1200 |

|

|

Feeder Power(KW) |

11 |

15 |

15 |

22 |

|

|

Drive Mode |

Motor Reducer |

Motor Reducer |

Motor Reducer |

Motor Reducer |

|

|

Crusher |

|||||

|

Device/Model |

CH430 |

HP300 |

HP400 |

HP300 |

|

|

Crusher Power(KW) |

132 |

220 |

315 |

220 |

|

|

Processing Capacity(t/h) |

150-200 |

110-440 |

135-630 |

110-440 |

|

|

Return Material Sieve |

|||||

|

Device/Model |

SX1536 |

SX1545 |

SX1545 |

SX1545 |

|

|

Number Of Screen Layers |

1 |

1 |

1 |

1 |

|

|

Belt Conveyor |

|||||

|

Main Belt Conveyor |

B1200 |

B1200 |

B1200 |

B1200 |

|

|

Side Belt Conveyor |

B1200 |

B1200 |

B1200 |

B1200 |

|

|

Material Return Belt Conveyor |

B500 |

B500 |

B500 |

B500 |

|

|

Drive Mode |

Motor Reducer |

Motor Reducer |

Motor Reducer |

Motor Reducer |

|

|

Machine Power(KW) |

184.4 |

293.4 |

388.4 |

293.4 |

|

|

Power System(KW) |

Cummins 330 |

Cummins 560 |

Cummins 560 |

Cummins 93 |

|

Attention: The generator is an external generator set, and customers need to purchase it themselves or Shunzhi can provide a quotation.The standard quotation does not include the generator. For more models, please consult Shunzhi.