YK Series Vibrating Screen

YK Series Vibrating Screen

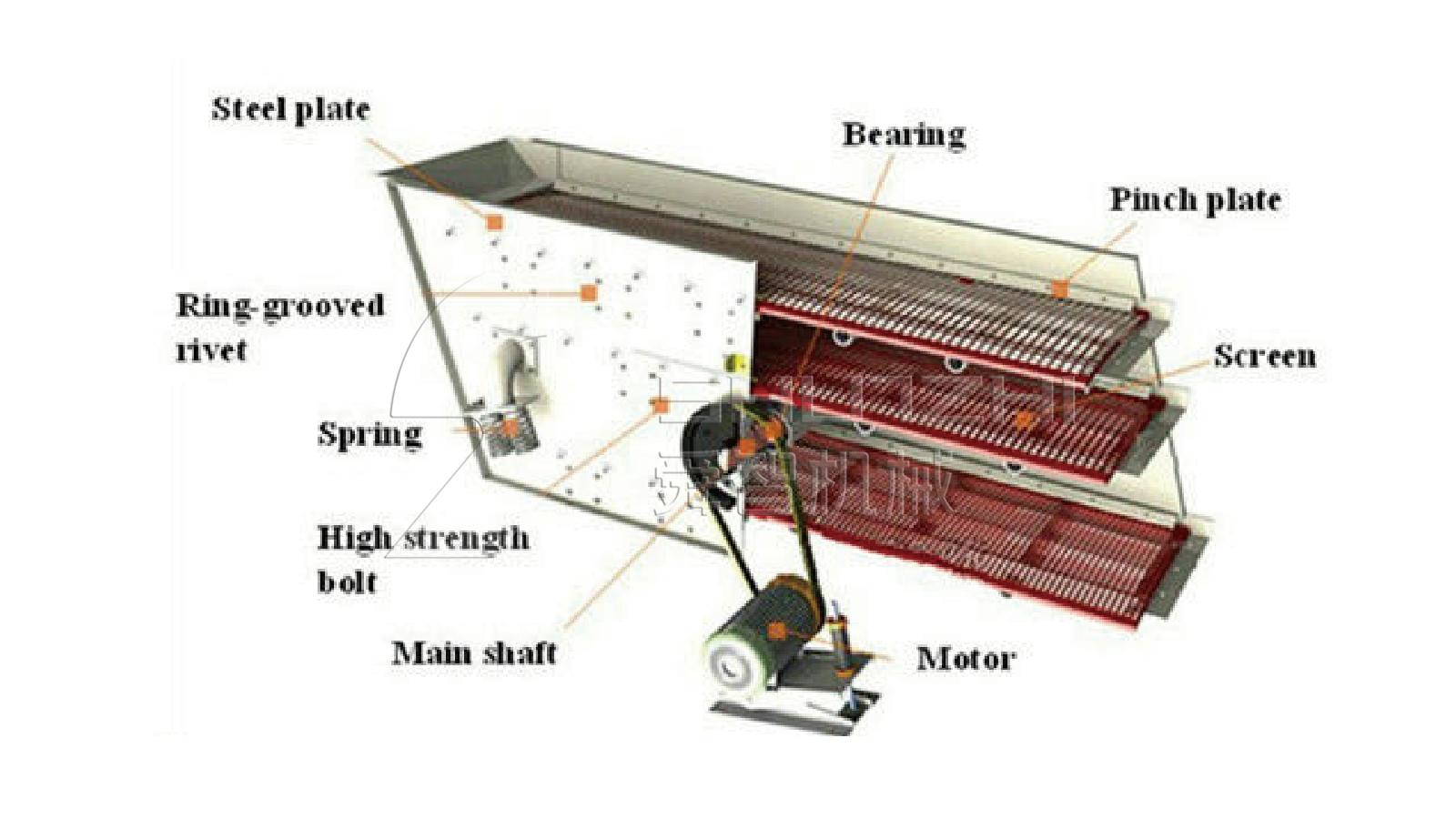

YK series vibrating screen adopts a dedicated exciter, which has higher excitation force and larger amplitude. The body adopts non welding technology to ensure its strength, and there are multiple screen selection options to ensure stronger adaptability. This series of vibrating screens is widely used in industries such as sand and gravel aggregates, metal mines, etc.

Advantages Of YK Series Vibrating Screen

Advantages Of YK Series Vibrating Screen

YK series vibrating screens have been widely welcomed and recognized in the market for their advantages such as efficient screening, reliable structure, low noise, good environmental protection, simple operation, and convenient maintenance.

YK series vibrating screen is a high-efficiency vibrating screening equipment that uses

an inner eccentric shaft or block eccentricity as the excitation force. It has the

advantages of a stable structure, high screening efficiency, low power consumption, and

low noise. It is widely used in product grading and screening operations in many

industries.

YK series vibrating screens are widely used in quarrying sand and gravel, as well as

product grading in coal preparation, mineral processing, building materials, power, and

chemical industries. Its efficient and stable screening performance has been recognized

by the majority of users.

YK series vibrating screens generally have a large processing capacity and can meet the

needs of production lines of different sizes.

YK1548 type of vibrating screen is suitable for screening small and medium-sized

materials. YK1860 performs well when processing large amounts of materials; the YK2160

vibrating screen is widely praised for its powerful processing capacity and efficient

screening performance; YK2460 and YK2870, as a large vibrating screen in the YK series,

has significant advantages in screening large materials.

Efficient screening mechanism: YK series vibrating screens use internal eccentric shafts

or block eccentricity as excitation force, and the eccentric shaft or eccentric block is

driven by the motor to rotate so that the vibrating screen moves in a circular

trajectory of up, forward, and down and backward. This motion trajectory allows the

screened material to slip through the screen evenly and quickly, thereby improving the

screening efficiency.

Multiple screening specifications: The mesh size of the YK series vibrating screen is

generally between 3-50mm, which can be adjusted according to the screening requirements

of different materials. At the same time, its processing capacity can reach 250t/h,

ensuring efficient screening without blocking holes.

The screen materials of the YK series vibrating screen are mostly made of wear-resistant

and corrosion-resistant materials, such as perforated plate screens, metal woven meshes,

etc. These materials have a long service life and stable screening effect, which can

ensure that the vibrating screen can still operate normally under harsh working

conditions.

The design of the screen takes into account the fluidity, screening efficiency, and wear

resistance of the material. By optimizing the structure and material of the screen, the

YK series vibrating screen can ensure that the material is evenly distributed on the

screen, reduce the phenomenon of hole blocking, and improve the screening efficiency.

Application Of YK Series Vibrating Screen

Application Of YK Series Vibrating Screen

YK series vibrating screens are widely used in many industries such as ore dressing, coal dressing, building materials, power, and chemical industry. Its diverse models and specifications can meet the production needs of different users. Whether it is a large production line or a small production line, you can find a suitable YK series vibrating screen model.

What Is The Working Principle Of YK Series Vibrating Screen

What Is The Working Principle Of YK Series Vibrating Screen

Excitation force generation:The YK series vibrating screen uses an inertial

vibrator as a

vibration source, which is composed of an eccentric block, bearing seat, sealing cover,

motor, etc. The motor drives the eccentric block to rotate, generating centrifugal force,

which is then transmitted to the screen box through the bearing seat and sealing cover,

causing the screen box to vibrate.

Screening process:Under the action of vibration force, the material on the

screen surface

moves, and the material smaller than the screen hole size passes through the screen, while

the material larger than the screen hole size remains on the screen surface, thereby

realizing the screening operation.

|

Model |

Screen size(mm) |

Layers |

Mesh size(mm) |

Max feed size(mm) |

Capacity |

Motor power(KW) |

Vibrating frequency(RPM) |

Double Amplitude(mm) |

|

2YK1237 |

3700*1200 |

2 |

3-80 |

100 |

10-80 |

11 |

750-950 |

6-9 |

|

3YK1237 |

3700*1200 |

3 |

3-80 |

100 |

10-80 |

11 |

750-950 |

6-9 |

|

2YK1548 |

4800*1500 |

2 |

3-80 |

100 |

30-200 |

11 |

750-950 |

6-9 |

|

3YK1548 |

4800*1500 |

3 |

3-80 |

100 |

30-200 |

15 |

750-950 |

6-9 |

|

4YK1548 |

4800*1500 |

4 |

3-80 |

100 |

30-200 |

15 |

750-950 |

6-9 |

|

2YK1848 |

4800*1800 |

2 |

3-80 |

100 |

50-250 |

18.5 |

750-950 |

6-9 |

|

3YK1848 |

4800*1800 |

3 |

3-80 |

100 |

50-250 |

18.5 |

750-950 |

6-9 |

|

2YK1860 |

6000*1800 |

2 |

3-80 |

100 |

60-300 |

18.5 |

750-950 |

6-9 |

|

3YK1860 |

6000*1800 |

3 |

3-80 |

100 |

60-300 |

22 |

750-950 |

6-9 |

|

4YK1860 |

6000*1800 |

4 |

3-80 |

100 |

60-300 |

30 |

750-950 |

6-9 |

|

2YK2160 |

6000*2100 |

2 |

3-80 |

100 |

80-400 |

22 |

750-950 |

6-9 |

|

3YK2160 |

6000*2100 |

3 |

3-80 |

100 |

80-400 |

30 |

750-950 |

6-9 |

|

4YK2160 |

6000*2100 |

4 |

3-80 |

100 |

80-400 |

30 |

750-950 |

6-9 |

|

2YK2460 |

6000*2400 |

2 |

3-80 |

200 |

100-500 |

30 |

750-950 |

6-9 |

|

3YK2460 |

6000*2400 |

3 |

3-80 |

200 |

100-500 |

37 |

750-950 |

6-9 |

|

4YK2460 |

6000*2400 |

4 |

3-80 |

200 |

100-500 |

37 |

750-950 |

6-9 |

|

2YK2870 |

7000*2800 |

2 |

3-80 |

200 |

100-700 |

2x22 |

750-950 |

6-9 |

|

3YK2870 |

7000*2800 |

3 |

3-80 |

200 |

100-700 |

2x30 |

650-850 |

6-9 |

|

4YK2870 |

7000*2800 |

4 |

3-80 |

200 |

100-700 |

2x30 |

650-850 |

6-9 |

|

2YK3075 |

7500*3000 |

2 |

3-80 |

200 |

150-800 |

2x30 |

650-850 |

6-9 |

|

3YK3075 |

7500*3000 |

3 |

3-80 |

200 |

150-800 |

2x30 |

650-850 |

6-9 |

|

2YK3675 |

7500*3600 |

2 |

3-80 |

200 |

150-800 |

2x37 |

650-1000 |

6-9 |

|

3YK3675 |

7500*3600 |

3 |

3-80 |

200 |

150-800 |

2x37 |

650-1000 |

6-9 |