VSI Series High-Efficiency Impact Crusher

VSI Series High-Efficiency Impact Crusher

The VSI series vertical impact crusher adopts a high-speed design and thin oil lubrication to ensure stable operation of the equipment. The new "N" series adopts a deep cavity rotor design with higher processing capacity. The sand making mode can increase the sand production rate by 10%. This series of products is widely used in the sand and gravel aggregate industry, which can produce both machine-made sand and high-quality aggregates through shaping.

Advantages Of VSI Series High-Efficiency Impact Crusher

Advantages Of VSI Series High-Efficiency Impact Crusher

VSI sand-making machine has the advantages of high processing capacity, excellent finished sand shape, high wear resistance, easy maintenance, safety and reliability, and wide application fields. It is ideal sand-making equipment in construction, sand and gravel, cement, metallurgy, and other industries.

Designed with a welded carbon steel frame and chrome iron feed plate, impeller shoes and external feed pipe, Shunzhi vertical shaft impact crusher is highly robust and reliable in working.

The sand and gravel particles produced by VSI sand making machine have good shape, cubic shape, uniform particle size and reasonable gradation. It is a professional sand making and shaping equipment.

Ranging from 1700~1900r/min rotation speed to 1100~1310r/min speed, our machine provides precise control over product quality and gradation.

The maximum center and ring feeding throughput capacity reaches 500~640t/h, while the center feeding throughput capacity goes up to 250~360t/h, enabling our machine to be widely used in multiple applications.

Application Of VSI Series High-Efficiency Impact Crusher

Application Of VSI Series High-Efficiency Impact Crusher

Applicable Materials:Suitable for crushing cobblestone, basalt, granite, iron

ore, copper ore, cement, artificial

sand, fluorite, limestone.

Applicable Fields:Widely used in Aggregate shaping, machine-made sand, building

materials, mining, chemical

industry, metallurgy, road construction, water conservancy and other industries.

What Is The Working Principle Of VSI Series High-Efficiency Impact Crusher

What Is The Working Principle Of VSI Series High-Efficiency Impact Crusher

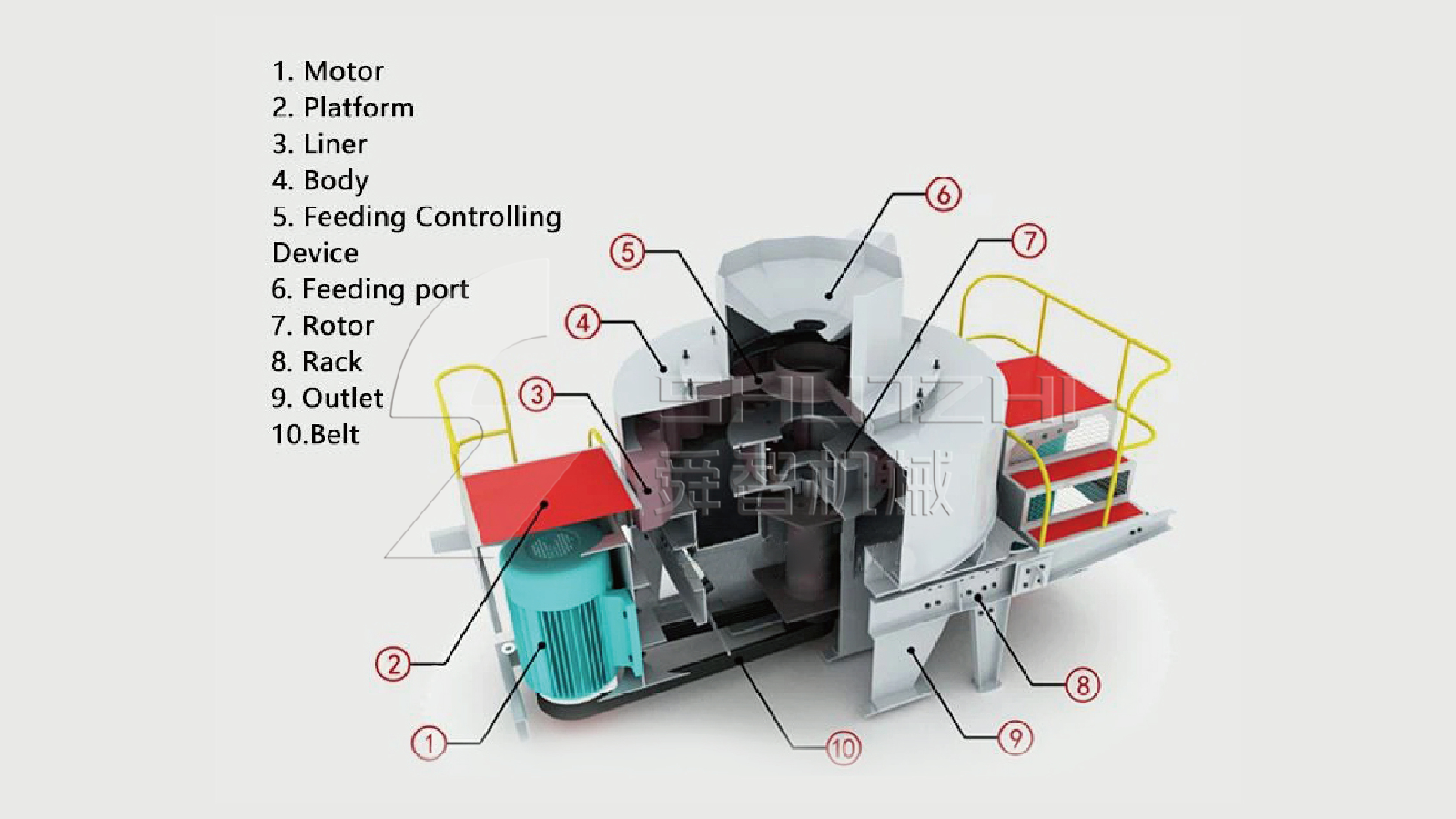

The sand-making machine is composed of seven parts: a feeding hopper, a distributor, a

vortex crushing chamber, an impeller body, a main shaft assembly, a base, a transmission

device, and a motor.

The material falls vertically into the high-speed rotating impeller from the upper part of

the machine. Under the action of high-speed centrifugal force, it will collide with another

part of the material shunted around the impeller in the form of an umbrella. The material

forms a vortex between the casings, collides and rubs each other many times, is crushed, and

is directly discharged from the lower part to form a closed circuit for multiple cycles.

After being controlled by the screening equipment, the finished product reaches the required

particle size.

|

Model |

Capacity |

The max feeding size(mm) |

Speed rpm |

Double Motor Power(KW) |

Weight(t) |

||

|

Waterfall Discharging And Central feeding |

Full Center feeding |

Soft stone |

Hard stone |

||||

|

VSI7611 |

120-180 |

60-90 |

35 |

30 |

1700-1930 |

2*55 |

10 |

|

VSI7615N |

150-280 |

70-140 |

35 |

30 |

1700-1930 |

2*75 |

8.6 |

|

VSI8518 |

200-260 |

100-130 |

40 |

35 |

1520-1690 |

2*90 |

12.5 |

|

VSI8522N |

240-380 |

120-200 |

40 |

35 |

1500-1700 |

2*110 |

12 |

|

VSI9526 |

300-380 |

150-190 |

45 |

40 |

1360-1510 |

2*132 |

14.5 |

|

VSI9532N |

350-400 |

180-280 |

45 |

40 |

1350-1510 |

2*160 |

17.5 |

|

VSI1140 |

450-520 |

225-260 |

50 |

45 |

1180-1300 |

2*200 |

19 |

|

VSI1145N |

500-640 |

250-360 |

50 |

45 |

1100-1310 |

2*160 |

27.5 |

|

VSI1150N |

450-545 |

344-368 |

55 |

45 |

1000-1300 |

2*250 |

20 |

|

VSI1263N |

545-583 |

454-486 |

60 |

50 |

900-1200 |

2*315 |

23 |