STZ Series Dehydration Screen

STZ Series Dehydration Screen

It adopts dual motor synchronization technology, universal eccentric block and adjustable amplitude vibrator. Through the synchronous reverse operation of two independent vibrators, the excitation force provided to the screen machine causes the material to jump in a straight line on the screen surface to achieve the purpose of dehydration, classification, deintermediation and desliming of the material. It can be used for sand washing in sand and gravel plants, coal slime recovery in coal preparation plants, dry discharge of tailings in mineral processing plants, etc. Therefore, it is also called sand and gravel dehydration screen, high-frequency dehydration screen, tailings screen, etc.

Advantages Of STZ Series Dehydration Screen

Advantages Of STZ Series Dehydration Screen

STZ Series Dehydration Screen play an important role in mining production due to their advantages of efficient dehydration, energy saving, and environmental protection, large processing capacity, simple structure, and strong adaptability.

STZ Series Dehydration Screen is a high-efficiency screening equipment that uses

vibration

force to achieve solid-liquid separation and dehydration.

STZ Series Dehydration Screen are widely used in mining, metallurgy, chemical industry,

building materials, environmental protection, and other industries, mainly in coal

preparation, ore dressing, electricity, sugar making, and other industrial sectors. It

can efficiently process medium and fine particles, and realize multiple functions such

as dry and wet classification, dehydration, de-medium, and desludging.

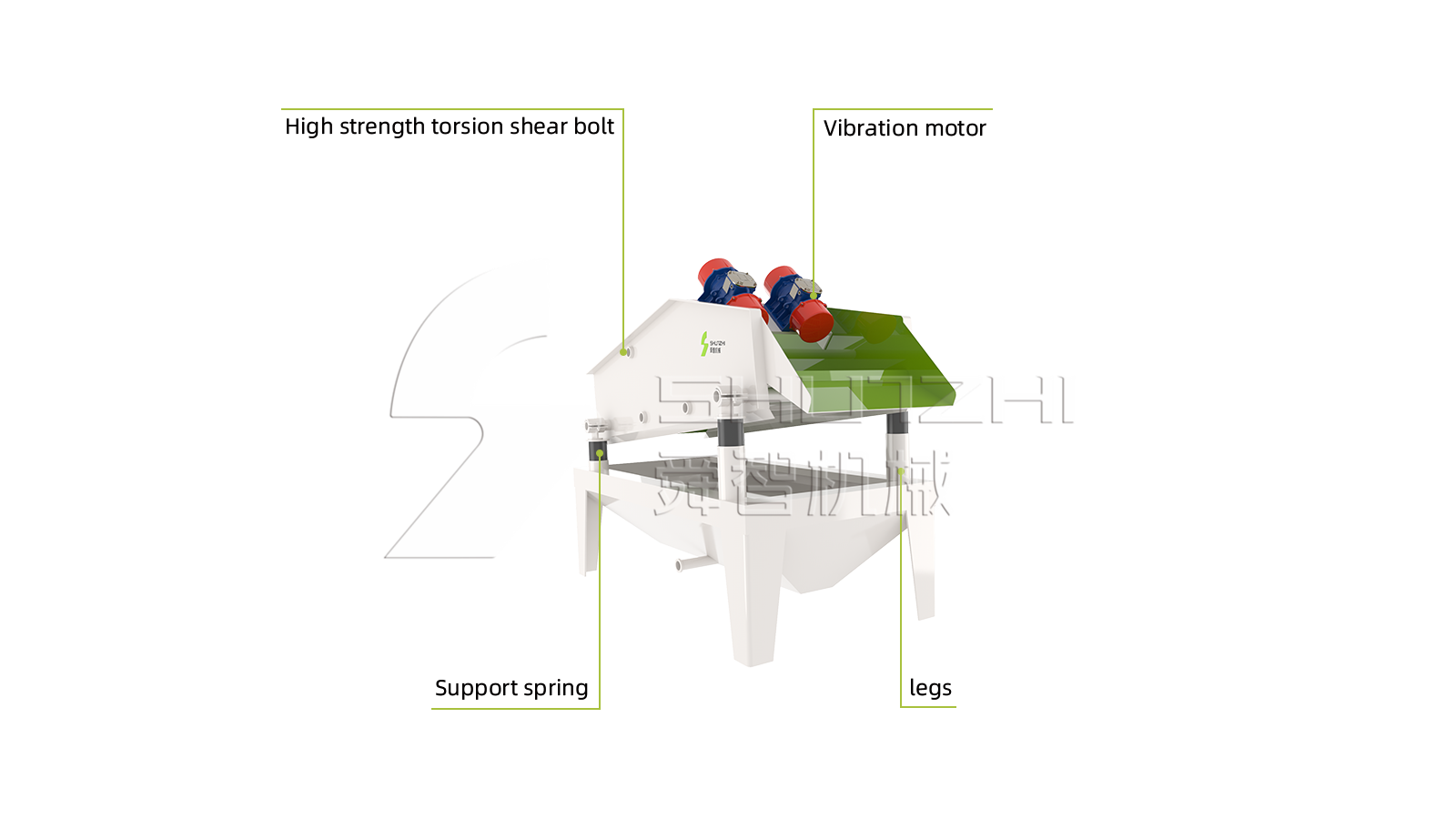

STZ Series Dehydration Screen is mainly composed of a screen box, screen, vibration

motor,

exciter, damping spring, and bracket.

STZ Series Dehydration Screen uses the exciting force generated by the vibration motor

to make the screen body vibrate periodically in the direction of the exciting force. The

material vibrates on the screen surface with the screen. Due to the gravity of the

material itself and the vibration of the screen, the material is thrown up on the screen

surface and produces a jumping motion to achieve separation.

Tailings treatment: including iron tailings, gold tailings, copper tailings, lead-zinc

tailings, graphite tailings, etc. The vibrating dehydration screen can effectively

remove

moisture from tailings and improve the dry discharge efficiency of tailings.

Non-metallic minerals: such as quartz sand, zircon sand, glass sand, building sand,

casting sand, building material sand, potassium feldspar, etc.

STZ Series Dehydration Screen is used for sand washing mountain sand. Through vibration

screening, impurities such as soil and stone powder in mountain sand can be removed, and

excess water can be removed at the same time, improving the quality and selling price of

sand and gravel.

STZ Series Dehydration Screen is used in conjunction with the thickener to effectively

remove moisture from the tailings and achieve dry discharge of the tailings.

Application Of STZ Series Dehydration Screen

Application Of STZ Series Dehydration Screen

The application of STZ Series Dehydration Screen is very extensive, involving many industries and fields. It is mainly used to achieve solid-liquid separation, dehydration, desludging, and de-mediation of materials.

What Is The Working Principle Of STZ Series Dehydration Screen

What Is The Working Principle Of STZ Series Dehydration Screen

STZ Series Dehydration Screen usually consist of key components such as screen boxes,

vibrators,

screens, and damping springs. When the equipment is started, the vibrator drives the screen

to vibrate at high frequencies. Materials are evenly placed on the screen and are affected

by vibration and gravity.

During this process, due to the vibration of the screen, the moisture and fine impurities in

the material are affected by centrifugal force and are forced to pass through the mesh of

the screen and be discharged. The screened materials, because their particle size exceeds

the mesh size of the screen, will be retained on the screen and continue to move forward

with the vibration of the screen.

The screen mesh design of mining dehydration screens usually has a certain inclination

angle,

which helps the material flow smoothly during the screening process. At the same time, the

vibration frequency and amplitude of the screen can be adjusted according to the properties

and processing needs of the material to achieve the best dehydration effect.

|

Model |

Feeding size(mm) |

Capacity |

Screen size(mm) |

Screen area(㎡) |

Power(KW) |

Overall size(mm) |

|

ST0924 |

≤10 |

10-20 |

900X2400 |

2.16 |

1.1X2 |

2480X1290X1220 |

|

ST1224 |

≤10 |

20-40 |

1200x2400 |

2.88 |

2.2X2 |

2480X1590X1430 |

|

ST1230 |

≤10 |

20-40 |

1200X3000 |

3.6 |

2.2X2 |

3080X1590X1500 |

|

ST1236 |

≤10 |

20-40 |

1200X3600 |

4.32 |

3.0X2 |

3680X1590X1500 |

|

SLZ1530 |

≤10 |

30-60 |

1500x3000 |

4.5 |

3.0X2 |

3080X1890X1440 |

|

ST1536 |

≤10 |

30-60 |

1500X3600 |

5.4 |

3.7X2 |

3680X1890X1450 |

|

ST1836 |

≤10 |

60-80 |

1800X3600 |

6.48 |

5.5X2 |

3720X2420X1930 |

|

ST1842 |

≤10 |

60-80 |

1800X4200 |

7.56 |

5.5X2 |

4370X2420X2100 |

|

ST2050 |

≤10 |

80-100 |

2000x5000 |

10 |

7.5x2 |

5200x2650x2430 |