SLZ Series Fine Sand Recycler

SLZ Series Fine Sand Recycler

The SLZ series fine sand recycler integrates dehydration and fine sand recovery, and successfully solves the problem of wet production.It solves the problem of loss of fine sand in finished sand and at the same time ensures that the moisture content in finished materials is reduced, making the production site more efficient.Adding cleanliness and tidiness, this equipment is widely used in finished sand cleaning in the sand and gravel aggregate industry and metal mine tailings treatment.and other industries

Advantages Of SLZ Series Fine Sand Recycler

Advantages Of SLZ Series Fine Sand Recycler

Fine sand recycling machine is the development of equipment for the slurry material dehydration, disengagement, deslimatization , the machine biggest feature is a good solution to the sand industry of the problem of fine sand loss.

The fine sand recycling machine has multiple functions, which can efficiently clean, dehydrate and classify the fine sand, greatly reducing the mud, impurities, and moisture content in the sand. Compared with the traditional sand washing machine, its clea.

It can be configured into different combinations according to different production requirements and working environments, which can not only improve work efficiency but also reduce energy consumption. Moreover, the recovered mud containing fine sand will have less waste residue deposited in the sedimentation tank, which is more conducive to environmental protection and water resource recycling.

The fine sand recycling machine has a reasonable structure, small footprint, simple installation, complete sand and gravel treatment at one time, strong operation stability, and high degree of automation.

Its investment cost is lower than ordinary sand washing machines and recycling machines. And there is no high-intensity impact operation, so the failure rate is also very low, and the maintenance cost will be small.

Application Of SLZ Series Fine Sand Recycler

Application Of SLZ Series Fine Sand Recycler

The fine sand recycling machine is usually used after the circular vibrating screen or drum sieve, and the mixture of sand, water, and mud after screening is fed into the feeding end of the sand recycling machine, and finally, the sand is cleaned, dehydrated, and deslimed. The finished sand after fine sand dehydration has a water content of 14-16% and a mud content of less than 3.5%. The fine sand recycling machine is mainly used for washing, dehydrating, and recycling the fine sand after the screening, which is simple and convenient.

What Is The Working Principle Of SLZ Series Fine Sand Recycler

What Is The Working Principle Of SLZ Series Fine Sand Recycler

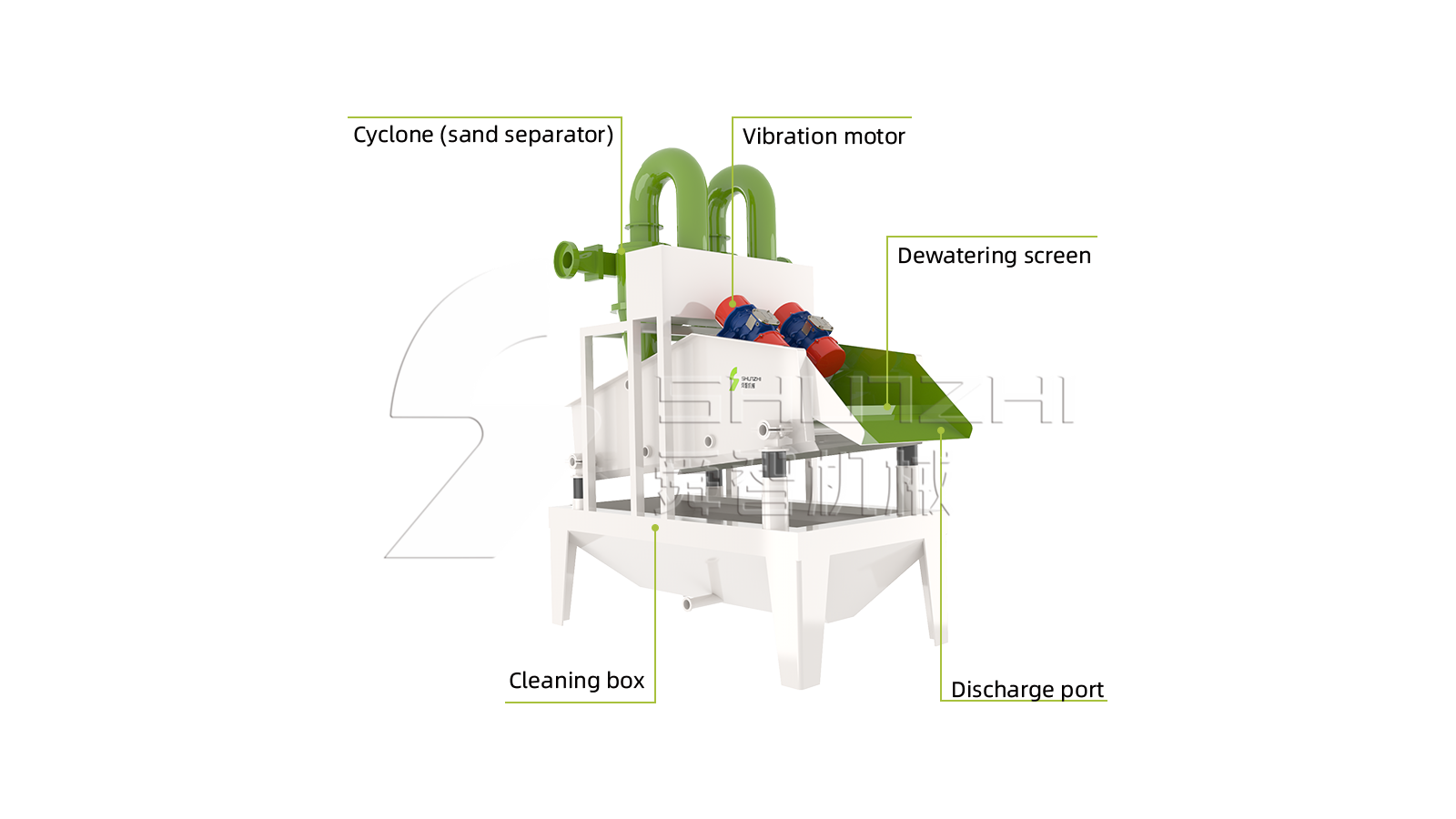

The fine sand recycling machine is composed of a dewatering screen, side liner, impeller

separator, vacuum high pressure pump, cleaning tank, high return water tank, motor, and

other components.

The sand-water mixture enters the cleaning box and is cleaned by the impeller separator.

After the sand and mud are separated, the sand and gravel enter the lower dewatering screen

for dehydration treatment, and the wastewater (containing a large amount of fine sand, mud,

dust, and other impurities) flowing out of the cleaning box is processed by the vacuum

high-pressure pump is transported to the high-pressure separator, and the fine sand after

centrifugal classification is sprayed to the upper layer of the dewatering screen through

the sand settling nozzle for dehydration treatment, and the remaining waste water, mud,

dust, and other impurities are discharged through the high-level return water tank. Coarse

sand is produced from the upper layer, and fine sand is produced from the lower layer or

mixed with coarse and fine sand.

|

Model |

Feeding size(mm) |

Capacity |

Screen size(mm) |

Screen area(㎡) |

Cyclone separator |

Power(KW) |

Overall size(mm) |

|

SLZ1224 |

≤10 |

20-40 |

1200x2400 |

2.88 |

300 |

19.4 |

2760X4850X2780 |

|

SLZ1530 |

≤10 |

30-60 |

1500x3000 |

4.5 |

300x2 |

36 |

3800X5500X3200 |

|

SLZ1842 |

≤10 |

40-80 |

1800x4200 |

7.56 |

350x2 |

48 |

4800X6000X4000 |

|

SLZ1845 |

≤10 |

40-80 |

1800x4500 |

8.1 |

350x2 |

52 |

5200X6000X4000 |

|

SLZ2442 |

≤10 |

100-150 |

2400x4200 |

10.08 |

300x4 |

82 |

4600X6250X3600 |

|

SLZ3048 |

≤10 |

120-200 |

3000x4800 |

14.4 |

350x4 |

104 |

5400X7000X4200 |

|

SLZ3661 |

≤10 |

150-250 |

3600x6100 |

21.96 |

300x6 |

134 |

6600X7000X4800 |