SC Series Jaw Crusher

SC Series Jaw Crusher

SC series jaw crusher is a high-performance jaw crusher manufactured by our company combining advanced technologies at home and abroad. The structure of this series of jaw crushers is reasonably designed, compact and efficient. The integrated motor bracket can install the motor at the rear of the crusher to ensure the reasonable tension of the V-belt. The optional integral base is convenient and quick to install.

Advantages Of SC Series Jaw Crusher

Advantages Of SC Series Jaw Crusher

SC series jaw crusher has a high production capacity and can meet the production needs of different scales. It is a coarse crusher with excellent performance, reliable structure, and easy operation, and is widely used in various fields.

SC Series Jaw Crusher is a productive and cost-effective coarse crusher. Compared with

traditional PE jaw crushers, the SC Series Jaw Crusher has lower energy consumption,

which helps to reduce production costs.

SC Series Jaw Crusher adopts a welded frame structure, which ensures its reliability and

fatigue resistance and can ensure trouble-free operation even in harsh operating

environments.

SC series jaw crushers have various models, covering equipment with different

specifications and performances to meet different scenarios and crushing

needs.Hot-selling models include SC96, SC106, SC100, SC120, SC116, etc.

Different types of crushers have different feed opening widths, depths, feed sizes,

discharge opening sizes, eccentric shaft speeds, production capacities, etc. They are

used to crush various ores and large materials.

The SC series jaw crusher is designed for high production and can meet the production

needs of large-scale mining, metallurgy, building materials, and other industries.

The discharge port gap of the SC series jaw crusher is adjustable, which means that

users

can adjust the discharge port size according to actual production needs, thereby

adjusting the capacity within a certain range.

Take the SC110 jaw crusher as an example, its feed particle size can reach ≤700mm, the

discharge particle size can be adjusted within the range of 70-200mm, and the capacity

can reach 200-400t/h.

Such a capacity level makes the SC110 jaw crusher an ideal choice for crushing materials

with higher hardness such as diabase, granite, marble, etc.

Application Of SC Series Jaw Crusher

Application Of SC Series Jaw Crusher

SC series jaw crusher is suitable for crushing a variety of materials, including river pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc. These materials have different hardness and characteristics, but a SC series jaw crusher can effectively crush them.

What Is The Working Principle Of SC Series Jaw Crusher

What Is The Working Principle Of SC Series Jaw Crusher

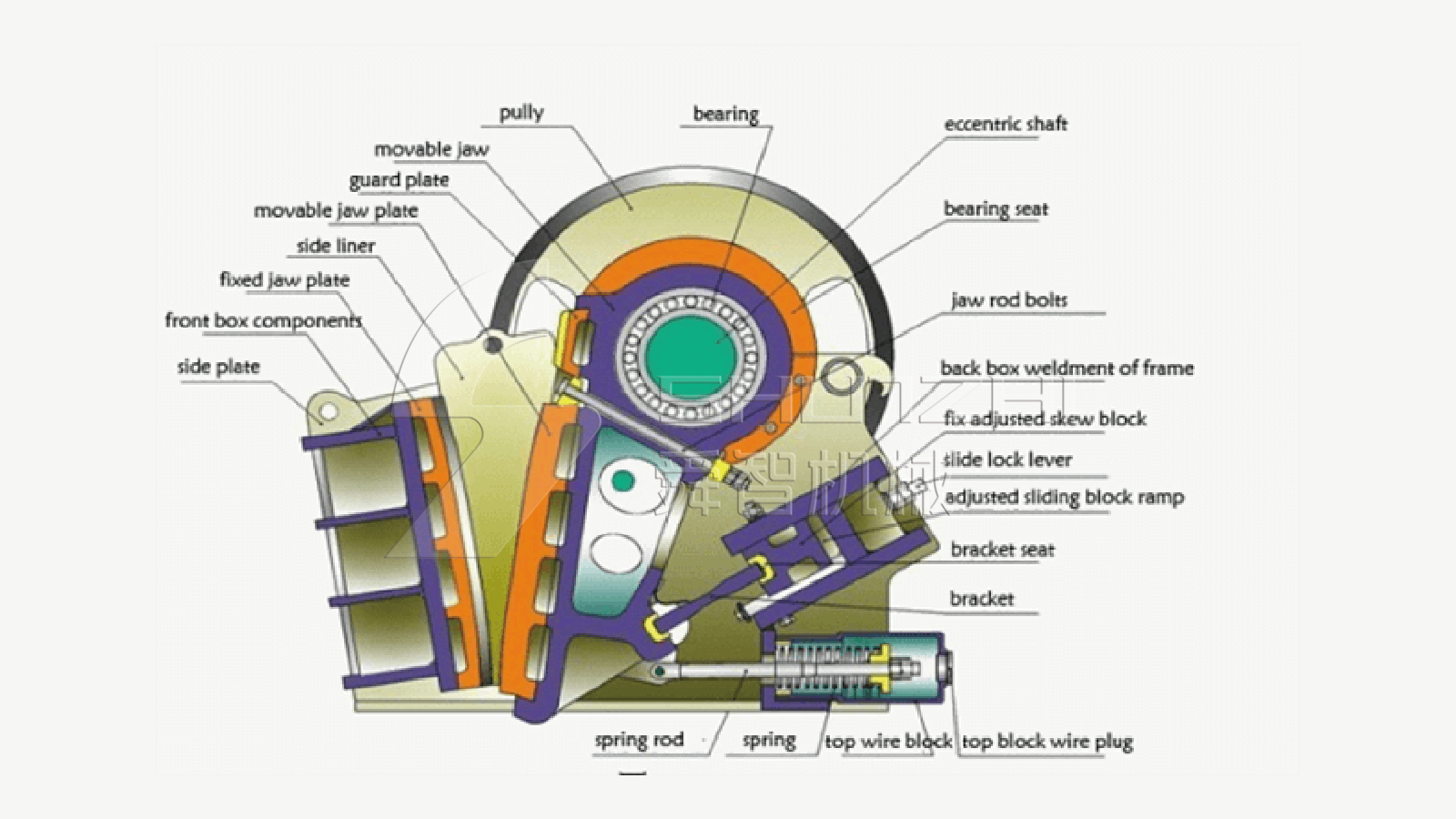

The SC series jaw crusher is mainly composed of a frame, an eccentric shaft, a movable jaw,

a

fixed jaw, a crushing chamber, an adjustment device, a transmission device, and a

lubrication system. Among them, the movable jaw and the fixed jaw are respectively installed

on both sides of the frame to form a crushing chamber. The eccentric shaft is installed on

the frame through a bearing and drives the movable jaw to perform periodic movements.

The crushing principle of the SC series jaw crusher mainly includes two modes of action:

extrusion and splitting. When the movable jaw approaches the fixed jaw, the material is

crushed by strong extrusion; at the same time, since the swing trajectory of the movable jaw

is not a strict linear motion, but has a certain arc trajectory, the material will also be

subject to a certain degree of splitting. Under the combined action of these two modes of

action, the material can be effectively crushed.

|

Model |

Feeding opening size(mm) |

Max feeding size(mm) |

Discharging opening size(mm) |

Capacity(t/h) |

Motor power(kw) |

Weight(t) |

|

SC80 |

510x800 |

430 |

40-175 |

55-375 |

75 |

9.52 |

|

SC96 |

580x930 |

490 |

70-175 |

140-455 |

90 |

11.87 |

|

SC106 |

700x1060 |

595 |

70-200 |

150-580 |

110 |

17.05 |

|

SC116 |

760x1150 |

650 |

70-200 |

165-520 |

132 |

21.5 |

|

SC120 |

870x1200 |

740 |

70-200 |

190-625 |

160 |

29.3 |

|

SC125 |

950x1250 |

800 |

100-250 |

205-787 |

160 |

43.9 |

|

SC140 |

1070x1400 |

900 |

125-250 |

290-845 |

200 |

55.6 |

|

SC150 |

1200x1400 |

1020 |

125-250 |

400-880 |

200 |

61.43 |

|

SC160 |

1200x1600 |

1020 |

150-300 |

520-1270 |

250 |

88.5 |