S Series Single-Cylinder Hydraulic Cone Crusher

S Series Single-Cylinder Hydraulic Cone Crusher

S serious multi-cylinder hydraulic cone crusher is mainly composed by main engine,motor, integral base, oil station and the electric control system.

S series single cylinder hydraulic cone crusher is one of the core products in our company.After years of application accumulation and improvement,all stable operation, simple structure, high degree of automation, strong production capacity.Widely used in metal mining, sand aggregate and other industries, with its excellent performance to ensure customers to achieve production value.

Advantages Of S Series Single-Cylinder Hydraulic Cone Crusher

Advantages Of S Series Single-Cylinder Hydraulic Cone Crusher

Single-cylinder cone crusher occupies an important position in the field of ore crushing with its advantages of efficient crushing capacity, stability and reliability, intelligent control, energy saving and environmental protection, easy maintenance, and wide application.

Single-cylinder hydraulic cone crusher is a cone crushing equipment that uses a

single-cylinder hydraulic system and is mainly used for medium and fine crushing

operations.

It is suitable for crushing high-hardness and highly abrasive ores and rocks, especially

widely used in the crushing of metal ores and building sand and gravel.

Single-cylinder cone crushers have the characteristics of high crushing

efficiency, moderate processing capacity, and wide application range.

S500 single-cylinder cone crusher has a larger production capacity (200-650t/h), higher

crushing efficiency, and a wider range of applications.

The single-cylinder hydraulic cone crusher adopts advanced design concepts, making it

compact in structure, small in space, and easy to install and layout.

The single-cylinder hydraulic cone crusher adopts a steep slope cone design with a large

swing frequency and large inclination, making its processing capacity about 40% greater

than that of ordinary cone crushers.

The laminated crushing principle is adopted, and the products after crushing are mostly

cubic structures, which reduces the needle-like materials and makes the particle size

more uniform.

The unique crushing cavity shape and layered crushing principle are adapted to produce a

crushing effect between particles, thereby significantly increasing the proportion of

cubes in the finished product and reducing needle-like stones.

Application Of S Series Single-Cylinder Hydraulic Cone Crusher

Application Of S Series Single-Cylinder Hydraulic Cone Crusher

sand and gravel crushing, mine crushing, building stone crushing, chemical production, roadbed construction, infrastructure construction, etc.

What Is The Working Principle Of S Series Single-Cylinder Hydraulic Cone Crusher

What Is The Working Principle Of S Series Single-Cylinder Hydraulic Cone Crusher

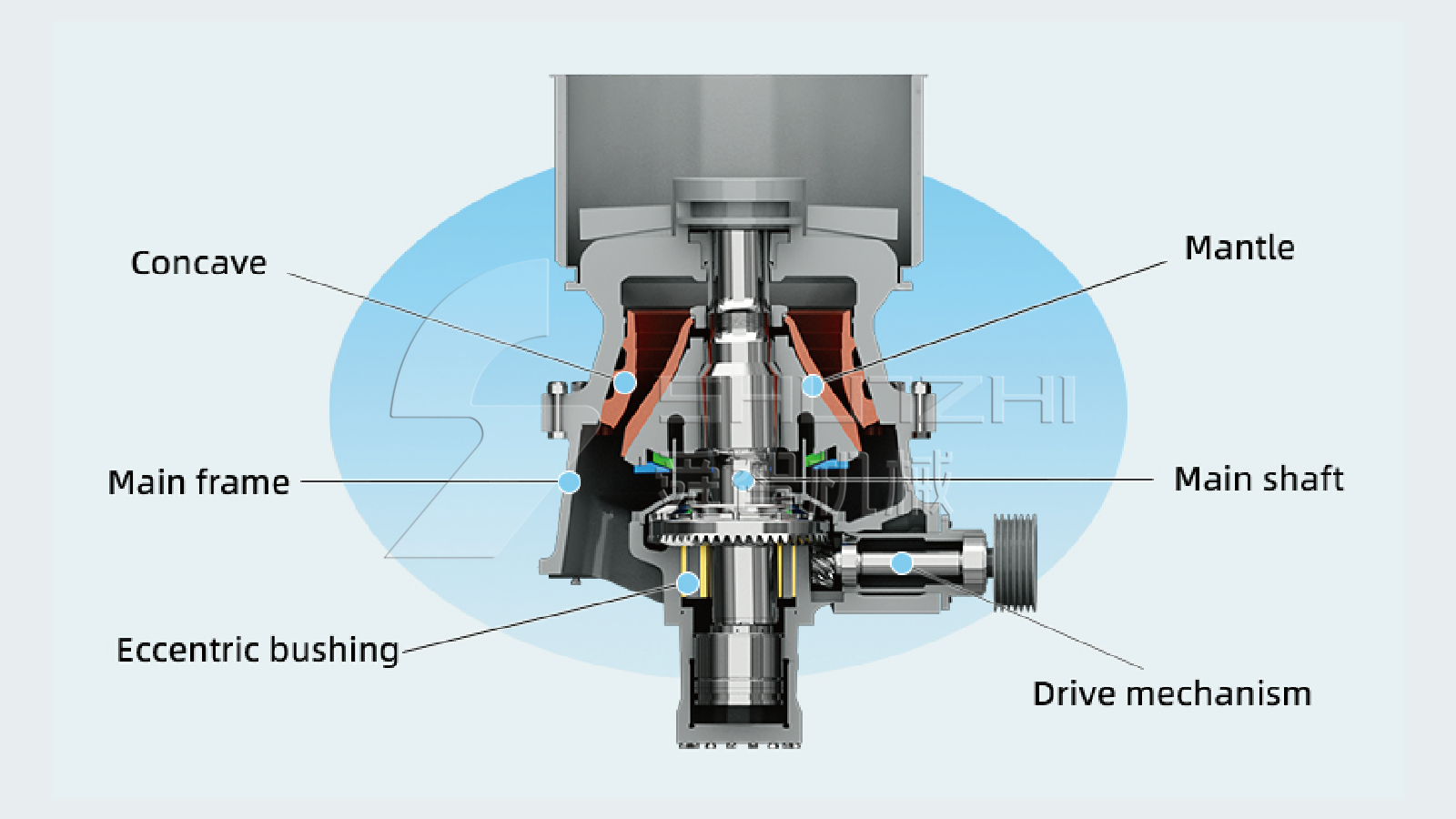

S single-cylinder cone crusher, that is, S series single-cylinder hydraulic cone crusher,

its working principle is mainly based on the relative motion between the movable cone and

the fixed cone to crush materials.

• Eccentric sleeve and main shaft: The main shaft installed in the eccentric sleeve will

make periodic movements as the eccentric sleeve rotates. This movement causes the cone

(moving cone) installed on the main shaft to also perform similar movements.

• Crushing wall and rolling mortar wall: The movement of the movable cone makes the crushing

wall on it sometimes approach and sometimes move away from the rolling mortar wall on the

fixed cone. When the crushing wall is close to the rolling mortar wall, the material between

the two is squeezed and sheared, thereby achieving crushing.

|

Model |

Cavity Type |

Max Feeding Size(mm) |

Discharging Opening Adjustment Scope(mm) |

Capacity(t/h) |

Motor Power(KW) |

Weight(t) |

|

CS430 |

Extra Coarse |

400 |

22-54 |

117-282 |

132 |

12 |

|

Coarse |

334 |

19-48 |

128-298 |

|||

|

Medium Coarse |

263 |

19-48 |

106-247 |

|||

|

CS440 |

Extra Coarse |

500 |

32-51 |

272-500 |

220 |

19.3 |

|

Coarse |

445 |

32-51 |

272-500 |

|||

|

Medium Coarse |

335 |

25-51 |

220-463 |

|||

|

CS660 |

Extra Coarse |

622 |

32-76 |

321-823 |

315 |

35.7 |

|

Coarse |

556 |

29-70 |

314-789 |

|||

|

CH430 |

Extra Coarse |

214 |

10-38 |

75-200 |

132 |

9.2 |

|

Coarse |

168 |

10-38 |

81-215 |

|||

|

Medium Coarse |

129 |

10-32 |

73-176 |

|||

|

Medium |

101 |

8-32 |

61-147 |

|||

|

Medium Fine |

86 |

6-25 |

52-116 |

|||

|

Fine |

62 |

4-25 |

42-100 |

|||

|

Extra Fine |

42 |

6-22 |

49-102 |

|||

|

CH440 |

Extra Coarse |

250 |

13-44 |

112-329 |

220 |

14.3 |

|

Coarse |

204 |

13-44 |

108-289 |

|||

|

Medium Coarse |

157 |

13-38 |

118-297 |

|||

|

Medium |

124 |

13-38 |

125-313 |

|||

|

Medium Fine |

98 |

13-38 |

108-272 |

|||

|

Fine |

96 |

8-38 |

80-231 |

|||

|

Extra Fine |

62 |

4-16 |

58-110 |

|||

|

CH660 |

Extra Coarse |

321 |

19-51 |

169-485 |

315 |

26.8 |

|

Coarse |

253 |

16-51 |

219-635 |

|||

|

Medium Coarse |

198 |

16-51 |

207-582 |

|||

|

Medium |

155 |

13-51 |

188-536 |

|||

|

Medium Fine |

133 |

13-44 |

184-521 |

|||

|

Fine |

96 |

13-44 |

149-423 |

|||

|

Extra Fine |

62 |

10-25 |

116-236 |