PE Series Jaw Crusher

PE Series Jaw Crusher

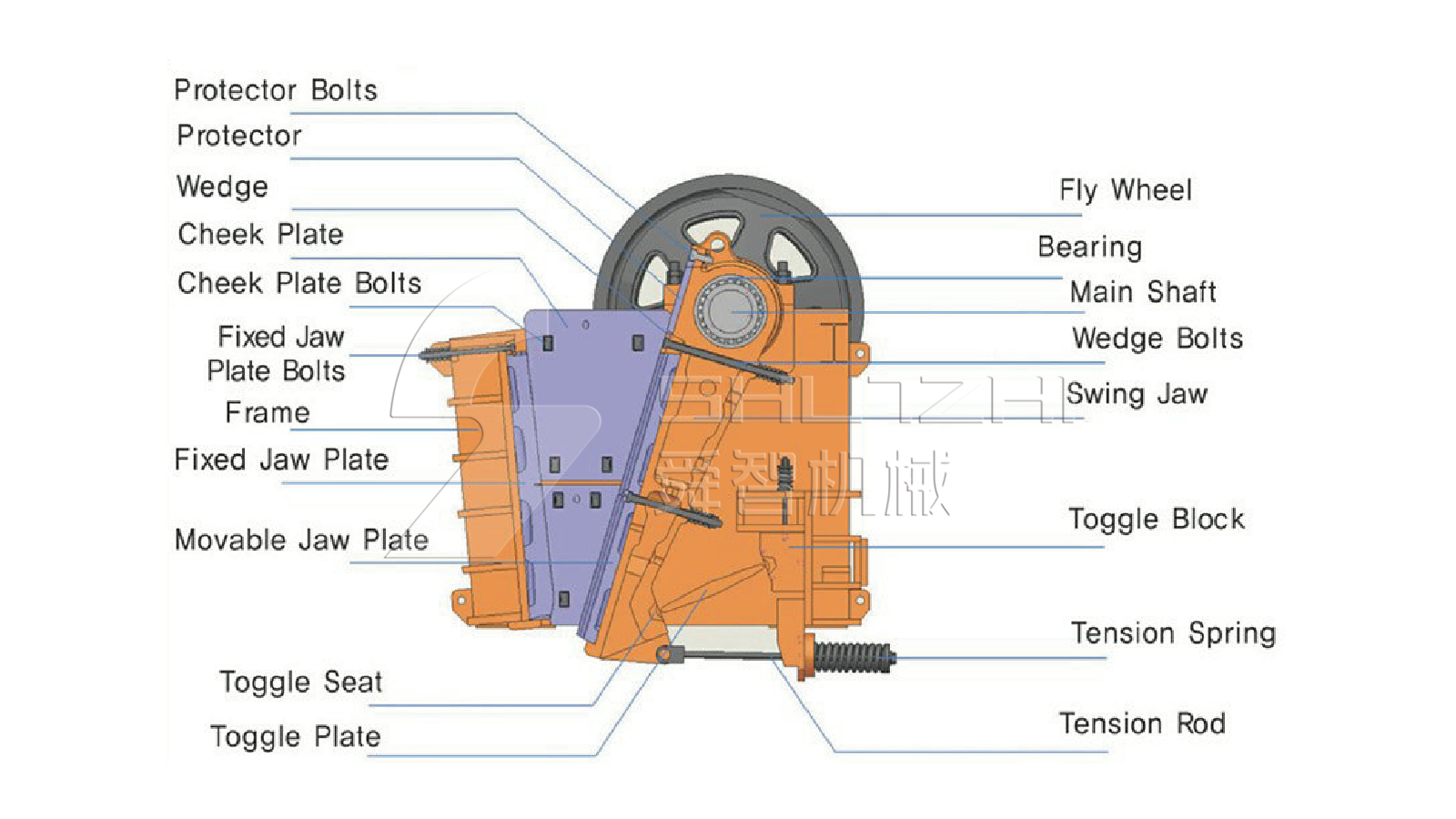

PE series jaw crusher is a high-performance jaw crusher manufactured by our company combining advanced technologies at home and abroad. The structure of this series of jaw crushers is reasonably designed, compact and efficient. The integrated motor bracket can install the motor at the rear of the crusher to ensure the reasonable tension of the V-belt.The optional integral base is convenient and quick to install.

Advantages Of PE Series Jaw Crusher

Advantages Of PE Series Jaw Crusher

PE fine jaw crusher has been widely used and recognized in many industries for its advantages such as high-efficiency crushing capacity, adjustable finished product size, compact structure, simple maintenance, strong stability, long service life, wide application range, environmental protection, and energy saving.

PE fine jaw crusher is a crusher that adopts the jaw crushing principle and drives the movable jaw to reciprocate according to a predetermined trajectory through an electric motor to perform multiple crushing actions such as squeezing, rubbing, and grinding on the materials entering the crushing chamber, thereby achieving fine crushing of the materials.

There are many models of PE fine jaw crusher, and different models of equipment have differences in feed port size, discharge port adjustment range, processing capacity, and motor power. Common models are PE 150×750, PE 250×750, PE 250×1000, PE 250×1200, PE 300×1300, etc., which are mainly used for medium and fine crushing of materials such as ore and rock.

PE fine jaw crusher adopts advanced crushing technology and optimized structural design, which can efficiently complete the crushing of materials. By adjusting the size of the discharge port, the particle size of the crushed material can be controlled to meet different production needs. Compared with the coarse crushing equipment, the discharge port of the PE fine jaw crusher is finer, the discharge effect is better, and the crushing is more complete.

The adjustment range of the discharge port of the PE series fine jaw crusher may be between 10-350mm. The discharge particle size of the PE fine jaw crusher will also be affected by factors such as material hardness, humidity, and viscosity. Materials of different hardness and properties will produce different crushing effects during the crushing process, thus affecting the particle size distribution of the discharged material.

Application Of PE Series Jaw Crusher

Application Of PE Series Jaw Crusher

PE fine jaw crusher can be used for crushing various metal ores and non-metallic ores, such as iron ore, copper ore, gold ore, manganese ore, limestone, dolomite, etc. It can crush large pieces of ore into smaller particles, which is convenient for subsequent mineral processing, smelting, or processing.

What Is The Working Principle Of PE Series Jaw Crusher

What Is The Working Principle Of PE Series Jaw Crusher

The motor transmits power to the eccentric shaft through the pulley, causing the eccentric

shaft to start rotating. The rotation of the eccentric shaft drives the movable jaw to

perform periodic opening and closing movements.

When the movable jaw rises, the angle between the toggle plate and the movable jaw

increases, thereby pushing the movable jaw plate closer to the fixed jaw plate; when the

movable jaw descends, the angle between the toggle plate and the movable jaw decreases, and

under the action of the pull rod and spring, the movable jaw plate leaves the fixed jaw

plate.

During the periodic opening and closing movement of the movable jaw, the material is

constantly squeezed, kneaded, and crushed. When the movable jaw approaches the fixed jaw,

the material is strongly squeezed and crushed; when the movable jaw leaves the fixed jaw,

the crushed material gradually falls to the discharge port under the action of gravity and

other materials in the crushing chamber.

|

Model |

Feeding opening size(mm) |

Max feeding size(mm) |

Discharging opening size(mm) |

Capacity(t/h) |

Motor power(kw) |

Weight(t) |

|

PE250x400 |

250x400 |

210 |

20-60 |

5-20 |

15 |

2.8 |

|

PE400x600 |

400x600 |

340 |

40-100 |

16-60 |

30 |

6.65 |

|

PE500x750 |

500x750 |

425 |

50-l00 |

40-110 |

55 |

11.73 |

|

PE600x900 |

600x900 |

500 |

65-180 |

80-180 |

55-75 |

16.13 |

|

PE750x1060 |

750x1060 |

630 |

80-180 |

110-320 |

90-110 |

30 |

|

PE900x1200 |

900x1200 |

780 |

95-225 |

220-450 |

110-132 |

49 |

|

PE1000x1200 |

1000x1200 |

850 |

195-280 |

280-550 |

110-132 |

51 |

|

PE1200x1500 |

1200x1500 |

1020 |

150-300 |

400-880 |

160-220 |

109 |

|

PEX150x750 |

150x750 |

120 |

18-48 |

8-25 |

15 |

35 |

|

PEX250x750 |

250x750 |

210 |

20-50 |

13-35 |

30 |

4.96 |

|

PEX250x1000 |

250x1000 |

210 |

25-60 |

16-52 |

30-37 |

6.5 |

|

PEX250x1200 |

250x1200 |

210 |

25-60 |

20-61 |

37-45 |

8.8 |

|

PEX300x1300 |

300x1300 |

250 |

20-90 |

25-95 |

55-75 |

12.6 |