HP Series Multi-Cylinder Hydraulic Cone Crusher

HP Series Multi-Cylinder Hydraulic Cone Crusher

HP series multi-cylinder hydraulic cone crusher mainly consists of main machine, motor, integral base, oil station and electronic control system.

HP series multi-cylinder hydraulic cone crusher is one of our company's core products. After years of application, accumulation and improvement,this series of products has stable operation, low failure rate and high efficiency, high one-time finished product, good finished product particle shape, and is widely used in metal mines,sand and gravel aggregates and other industries. With its excellent performance,it has become a tool for domestic customers to realize production value.

Advantages Of HP Series Multi-Cylinder Hydraulic Cone Crusher

Advantages Of HP Series Multi-Cylinder Hydraulic Cone Crusher

The multi-cylinder hydraulic cone crusher has the advantages of high-efficiency crushing capacity, flexible and adjustable discharge port, intelligent protection system, stable and reliable performance, energy saving and environmental protection, and easy maintenance and maintenance.

Multi-cylinder hydraulic cone crusher is a cone crusher equipped with multiple hydraulic cylinders. It uses the power of the hydraulic system and the crushing principle of the cone crusher to efficiently crush materials. It is an efficient and stable crushing equipment, mainly used for medium and fine crushing of materials of various hardness, such as ore, rock, etc.

HP series multi-cylinder hydraulic cone crusher has medium-scale crushing capacity and is suitable for medium and fine crushing operations. Compared with the HP200 series, the HP300 series has a larger crushing capacity and processing capacity. The HP400 series multi-cylinder hydraulic cone crusher belongs to the larger model in the HP series. The HP and above series multi-cylinder hydraulic cone crushers have greater crushing capacity and a wider range of applications.

The HP series multi-cylinder hydraulic cone crusher adopts advanced crushing principles

and structural design, with a large crushing ratio, and can efficiently complete various

medium, fine, and ultra-fine crushing operations. Its production capacity is

significantly improved compared with traditional cone crushers and can meet the needs of

large-scale production.

The HP series crushers adopt the proprietary "inter-particle lamination crushing"

principle, which significantly increases the cubic content in the finished product and

greatly increases the fine-grained materials, which well meets the use requirements of

high-quality aggregates.

The discharge particle size of the multi-cylinder hydraulic cone crusher can be adjusted

within a certain range to meet different production needs. Generally speaking, its

discharge adjustment range is relatively wide, and the discharge adjustment range of the

HP300 multi-cylinder hydraulic cone crusher can reach between 10-20mm.

The "inter-particle lamination crushing" principle is adopted to significantly increase

the cubic content in the finished product, the finished product has an excellent

particle shape, and the proportion of fine-grained materials is high.

Application Of HP Series Multi-Cylinder Hydraulic Cone Crusher

Application Of HP Series Multi-Cylinder Hydraulic Cone Crusher

Multi-cylinder hydraulic cone crushers are widely used in metal mines, such as the crushing of hard rock ores such as iron ore, copper ore, and gold ore. They can efficiently process these high-hardness ores and crush them to a particle size suitable for subsequent processing; in non-metallic mines, such as limestone, dolomite, quartz stone and other minerals, multi-cylinder hydraulic cone crushers are also often used.

What Is The Working Principle Of HP Series Multi-Cylinder Hydraulic Cone Crusher

What Is The Working Principle Of HP Series Multi-Cylinder Hydraulic Cone Crusher

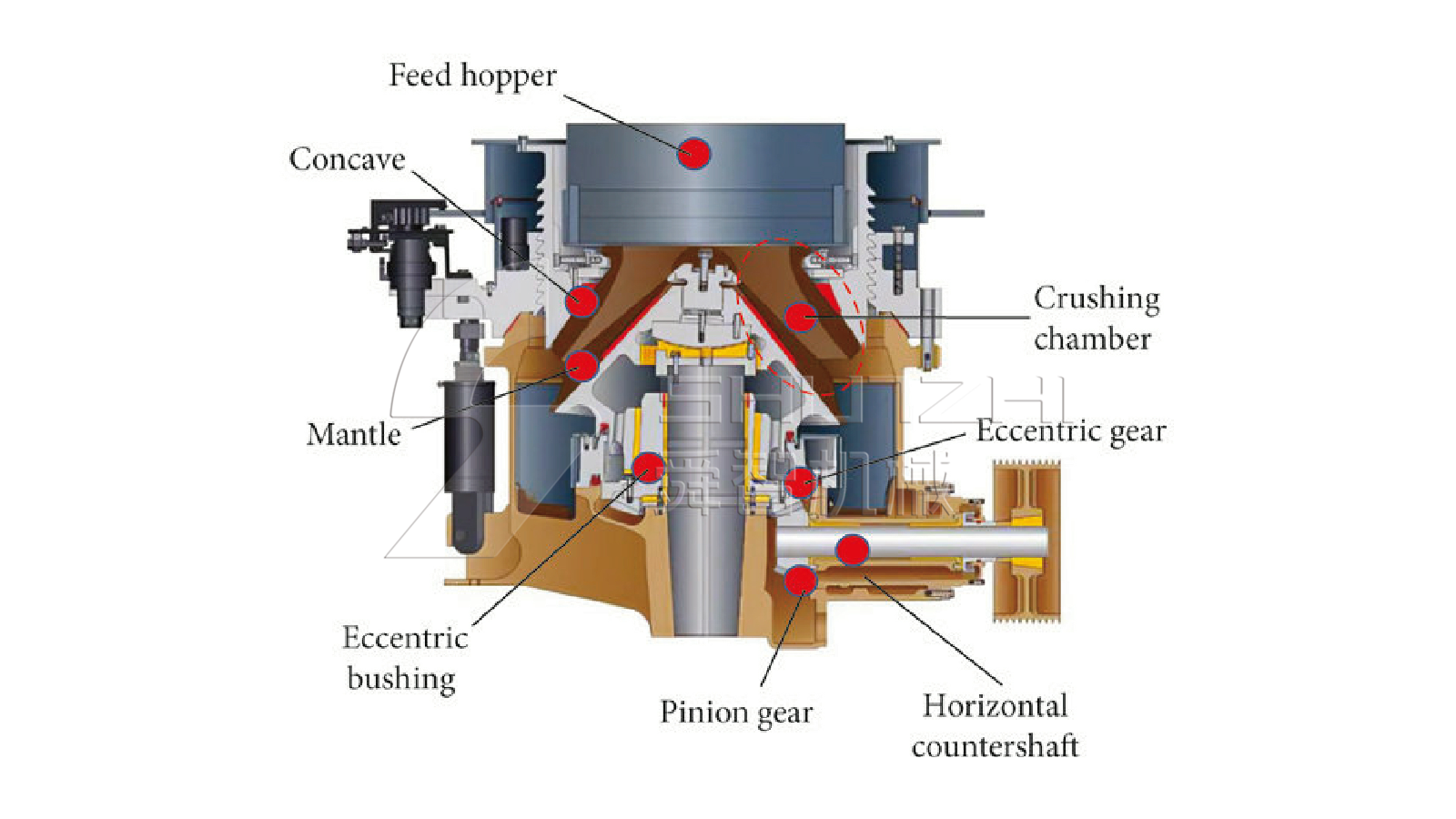

The multi-cylinder hydraulic cone crusher is mainly composed of a frame, a body, an

adjustment sleeve, a support sleeve, an eccentric sleeve, a bowl-shaped tile frame, a

transmission, a safety hydraulic cylinder, a feeding part, and a hydraulic system.

The material enters the crushing chamber from the feed port of the crusher and is squeezed

and crushed in the process of the moving cone and the fixed cone approaching and deviating

from each other.

When the moving cone approaches the fixed cone, the material is crushed by strong

squeezing; when the moving cone deviates from the fixed cone, the crushed material falls

from the bottom of the cone under the action of gravity.

The crushed material is discharged through the gap between the fixed cone and the moving

cone, that is, discharged from the machine cavity from the discharge port.

|

Model |

Cavity |

Feeding Opening Size(mm) |

Min Discharging Opening Size(mm) |

Capacity(t/h) |

Power(KW) |

Weight(t) |

|

HP200 |

Coarse |

185 |

19 |

145-250 |

160 |

14 |

|

Medium |

125 |

17 |

135-235 |

|||

|

Fine |

95 |

13 |

115-220 |

|||

|

Extra Fine |

75 |

10 |

90-190 |

|||

|

HP300 |

Extra Coarse |

230 |

25 |

220-440 |

250 |

20 |

|

Coarse |

210 |

20 |

190-380 |

|||

|

Medium |

150 |

15 |

175-320 |

|||

|

Fine |

105 |

10 |

145-280 |

|||

|

Extra Fine |

80 |

10 |

110-240 |

|||

|

HP400 |

Extra Coarse |

295 |

30 |

300-630 |

315 |

29 |

|

Coarse |

250 |

25 |

285-560 |

|||

|

Medium |

195 |

20 |

250-490 |

|||

|

Fine |

110 |

14 |

180-345 |

|||

|

Extra Fine |

90 |

10 |

135-320 |

|||

|

HP500 |

Extra Coarse |

330 |

20 |

425-790 |

400 |

38 |

|

Coarse |

285 |

25 |

370-700 |

|||

|

Medium |

200 |

20 |

330-605 |

|||

|

Fine |

133 |

16 |

270-535 |

|||

|

Extra Fine |

95 |

13 |

220-430 |

|||

|

HP800 |

Extra Coarse |

353 |

32 |

570-1200 |

630 |

64 |

|

Coarse |

297 |

32 |

520-1050 |

|||

|

Medium |

267 |

25 |

475-950 |

|||

|

Fine |

219 |

16 |

370-800 |