DT Series Belt Conveyor

DT Series Belt Conveyor

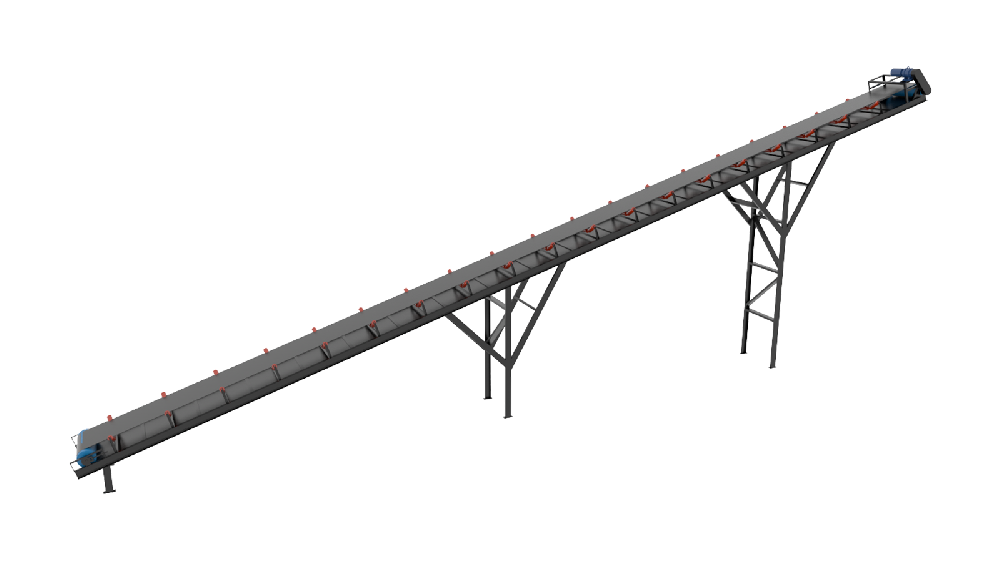

The DT series belt conveyor is a widely used material conveying equipment for mines, which is responsible for connecting crushing equipment at all levels, transporting materials, and storing finished products. It is designed according to national standards and is sturdy and durable.

Advantages Of DT Series Belt Conveyor

Advantages Of DT Series Belt Conveyor

The belt conveyor has the advantages of long transportation distance, large transportation capacity, small working resistance, easy installation, low power consumption, and less wear and tear.

The length of the line can be determined according to the needs, ranging from a few meters to tens of meters; it can be transported by a single unit or combined with multiple units.

A high-quality rubber belt conveyor is used, which is strong in pressure resistance and wear-resistant; accessories are produced according to high-quality standards and have a longer service life.

Because there is almost no relative movement between the material and the conveyor belt, the running resistance is small, the energy consumption is low, and the conveying capacity is strong.

C-shaped steel replaces the channel steel, and the special cast steel bearing seat is used. The main body of the frame is connected by bolts, which is more firm.

Application Of DT Series Belt Conveyor

Application Of DT Series Belt Conveyor

Belt conveyor is used to transferring stone aggregates and sand in mining, quarry, chemical industry, aggregate production, construction material recycling, powder grinding plant, ball mill plant, etc.

What Is The Working Principle Of DT Series Belt Conveyor

What Is The Working Principle Of DT Series Belt Conveyor

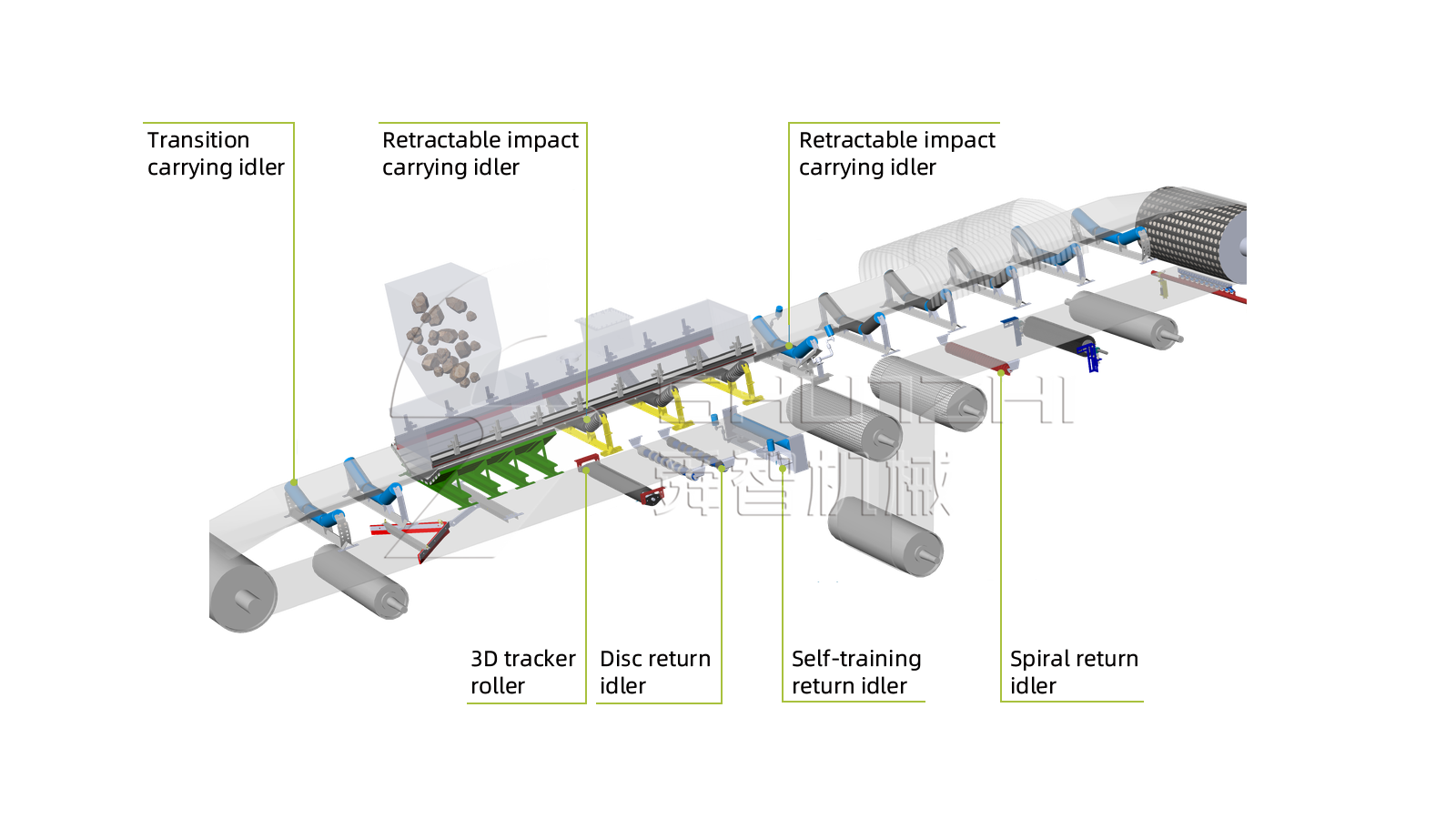

The belt conveyor is mainly composed of a frame, a conveyor belt, an idler roller, a pulley,

a tensioning device, a transmission device, etc.

The belt conveyor is a continuous transport machine with a conveyor belt as the traction and

carrying parts. The conveyor belt winds around the drive roller and various redirecting

rollers, and the tension device give proper tension. When working, driven by the drive

device, the friction and tension between the roller and the conveyor belt make the Conveyor

belt run. The material is continuously sent to the conveyor belt, and moves together with

the conveyor belt, so as to realize the conveying of the material.

|

Model |

Width(mm) |

Belt speed(m/s) |

Angle(°) |

Capacity |

Length(m) |

|

B500 |

500 |

1.25~4 |

0~17 |

100-200 |

Customization |

|

B650 |

650 |

1.25~4 |

0~17 |

100-300 |

Customization |

|

B800 |

800 |

1.25~4 |

0~17 |

200-400 |

Customization |

|

B1000 |

1000 |

1.25~4 |

0~17 |

200-500 |

Customization |

|

B1200 |

1200 |

1.25~4 |

0~17 |

200-800 |

Customization |

|

B1400 |

1400 |

1.25~4 |

0~17 |

300-1200 |

Customization |

|

B1600 |

1600 |

1.25~4 |

0~17 |

500-2000 |

Customization |

|

B2000 |

2000 |

1.25~4 |

0~17 |

500-3000 |

Customization |