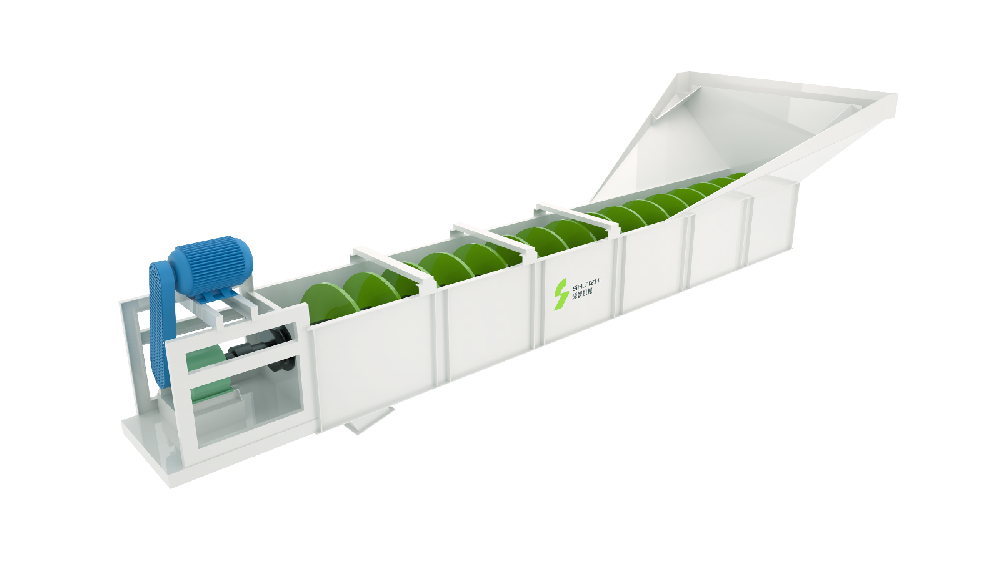

SXL series Spiral Sand Washing Machine

SXL series Spiral Sand Washing Machine

The spiral sand washing machine mainly stirs the sand and gravel through the spiral device inner the equipment,so that the soil and water in the sand and gravel are mixed and discharged from the overflow port on the equipment,the sand and gravel are gradually screened under the action of the spiral device, discharged from the discharge port at the top,thereby achieving the cleaning and screening effect of sand and gravel materials.

|

Model |

Feeding size(mm) |

Capacity |

Spiral diameter(mm) |

Channel length(mm) |

Power(KW) |

Overall size(mm) |

|

SXL760 |

≤10 |

20-40 |

760 |

7000 |

7.5 |

5700x1420x1900 |

|

SXL920 |

≤10 |

30-60 |

920 |

8000 |

11 |

8710X1630X208 |

|

SXL1120 |

≤10 |

40-80 |

1120 |

8000 |

18.5 |

9230X1840X2130 |

|

SXL1500 |

≤10 |

50-100 |

1500 |

8000 |

22 |

9620X2230X2480 |

|

2SXL0920 |

≤10 |

60-120 |

920 |

8000 |

11X2 |

8710X2600X2080 |

|

2SXL1120 |

≤10 |

80-160 |

1120 |

8000 |

18.5X2 |

9230X3050X2130 |

|

2SXL1500 |

≤10 |

120-250 |

1500 |

8000 |

22X2 |

9620X3730X2480 |

SXD series Wheel Sand Mashing Machine

SXD series Wheel Sand Mashing Machine

This series of sand washing machines adopts advanced technology and is developed based on the actual situation of the domestic sand and gravel industry.It is mainly used in construction sites, sand and gravel fields, hydropower station concrete precast plants, glass factories, quartz sand and fracturing sand for oil well backfill for washing, grading and Dehydration.

|

Model |

Feeding size(mm) |

Capacity |

Rotor diameter(mm) |

Channel length(mm) |

Power(KW) |

Overall size(mm) |

|

SXD2610 |

<10 |

30-80 |

2600 |

1000 |

4 |

3900X2900X2700 |

|

SXD3016 |

<10 |

60-120 |

3000 |

1600 |

5.5 |

4400X3300X3100 |

|

SXD3620 |

<10 |

80-160 |

3600 |

2000 |

7.5 |

5100X3750X3700 |

|

SXD3624 |

<10 |

120-200 |

3600 |

2400 |

11 |

5100X4100X3700 |

|

SXD4230 |

<10 |

160-250 |

4200 |

3000 |

15 |

6000X4800X4300 |

SLZ series Fine Sand Recycler

SLZ series Fine Sand Recycler

The SLZ series fine sand recycler integrates dehydration and fine sand recovery, and successfully solves the problem of wet production.It solves the problem of loss of fine sand in finished sand and at the same time ensures that the moisture content in finished materials is reduced, making the production site more efficient.Adding cleanliness and tidiness, this equipment is widely used in finished sand cleaning in the sand and gravel aggregate industry and metal mine tailings treatment.and other industries

|

Model |

Feeding size(mm) |

Capacity |

Screen size(mm) |

Screen area(㎡) |

Cyclone separator |

Power(KW) |

Overall size(mm) |

|

SLZ1224 |

<10 |

20-40 |

1200x2400 |

2.88 |

300 |

19.4 |

2760X4850X2780 |

|

SLZ1530 |

<10 |

30-60 |

1500x3000 |

4.5 |

300x2 |

36 |

3800X5500X3200 |

|

SLZ1842 |

<10 |

40-80 |

1800x4200 |

7.56 |

350x2 |

48 |

4800X6000X4000 |

|

SLZ1845 |

<10 |

40-80 |

1800x4500 |

8.1 |

350x2 |

52 |

5200X6000X4000 |

|

SLZ2442 |

<10 |

100-150 |

2400x4200 |

10.08 |

300x4 |

82 |

4600X6250X3600 |

|

SLZ3048 |

<10 |

120-200 |

3000x4800 |

14.4 |

350x4 |

104 |

5400X7000X4200 |

|

SLZ3661 |

<10 |

150-250 |

3600x6100 |

21.96 |

300x6 |

134 |

6600X7000X4800 |

STZ series Dehydration Screen

STZ series Dehydration Screen

It adopts dual motor synchronization technology, universal eccentric block and adjustable amplitude vibrator. Through the synchronous reverse operation of two independent vibrators, the excitation force provided to the screen machine causes the material to jump in a straight line on the screen surface to achieve the purpose of dehydration, classification, deintermediation and desliming of the material. It can be used for sand washing in sand and gravel plants, coal slime recovery in coal preparation plants, dry discharge of tailings in mineral processing plants, etc. Therefore, it is also called sand and gravel dehydration screen, high-frequency dehydration screen, tailings screen, etc.

|

Model |

Feeding size(mm) |

Capacity |

Screen size(mm) |

Screen area(㎡) |

Power(KW) |

Overall size(mm) |

|

ST0924 |

<10 |

10-20 |

900X2400 |

2.16 |

1.1X2 |

2480X1290X1220 |

|

ST1224 |

<10 |

20-40 |

1200x2400 |

2.88 |

2.2X2 |

2480X1590X1430 |

|

ST1230 |

<10 |

20-40 |

1200X3000 |

3.6 |

2.2X2 |

3080X1590X1500 |

|

ST1236 |

<10 |

20-40 |

1200X3600 |

4.32 |

3.0X2 |

3680X1590X1500 |

|

SLZ1530 |

<10 |

30-60 |

1500x3000 |

4.5 |

3.0X2 |

3080X1890X1440 |

|

ST1536 |

<10 |

30-60 |

1500X3600 |

5.4 |

3.7X2 |

3680X1890X1450 |

|

ST1836 |

<10 |

60-80 |

1800X3600 |

6.48 |

5.5X2 |

3720X2420X1930 |

|

ST1842 |

<10 |

60-80 |

1800X4200 |

7.56 |

5.5X2 |

4370X2420X2100 |

|

ST2050 |

<10 |

80-100 |

2000x5000 |

10 |

7.5x2 |

5200x2650x2430 |