ST Track-mounted Jaw crusher

ST Track-mounted Jaw crusher

ST series crawler jaw crushers have independent power units and can walk independently. They are widely used in primary crushing in mines.

|

Device/Model |

STC96 |

STC106 |

STC116 |

STC120 |

|

|

Feeding Department |

|||||

|

Bin Volume(m³) |

4 |

6 |

6 |

9 |

|

|

Feeder Model |

FD9638 |

FD1142 |

FD1142 |

FD1349 |

|

|

Feeder Power(KW) |

11 |

15 |

15 |

22 |

|

|

Maximum Feeding Particle Size(mm) |

450 |

580 |

580 |

630 |

|

|

Crusher |

|||||

|

Device/Model |

SC96 |

SC106 |

SC116 |

SC120 |

|

|

Crusher Power(KW) |

90 |

110 |

132 |

160 |

|

|

Feed Inlet Size(mm) |

580x930 |

700x1060 |

760x1150 |

870x1200 |

|

|

Processing Capacity(t/h) |

140-450 |

150-580 |

190-625 |

205-780 |

|

|

Belt Conveyor |

|||||

|

Main Belt Conveyor |

B1000 |

B1000 |

B1200 |

B1200 |

|

|

Side Belt Conveyor |

B650 |

B650 |

B650 |

B650 |

|

|

Drive Mode |

Motor Reducer |

Motor Reducer |

Motor Reducer |

Motor Reducer |

|

|

Iron Remover |

RCYD-10 |

RCYD-10 |

RCYD-12 |

RCYD-12 |

|

|

Machine Power(KW) |

121.2 |

141.2 |

168 |

196 |

|

|

Power System(KW) |

Cummins 330 |

Cummins 330 |

Cummins 330 |

Cummins 400 |

|

Attention:There are two types of crawler mobile crushing stations: pure electric drive and vehicle-mounted power drive. Please consult Shunzhi Machinery according to your needs.

ST Track-mounted Cone crusher

ST Track-mounted Cone crusher

ST series crawler cone crusher has an independent power unit and can walk independently.It has a complete feeding, crushing, screening, and returning system.It can work alone or can be combined with jaw breaking,screening and other equipment to form a production line to meet different customer requirements.

|

Device/Model |

STP430RS |

STH300RS |

STH400RS |

STH300RS(E) |

|

|

Feeding Department |

|||||

|

Bin Volume(m³) |

5 |

6.5 |

6.5 |

6.5 |

|

|

Feeder Model |

B1000 |

B1200 |

B1200 |

B1200 |

|

|

Feeder Power(KW) |

11 |

15 |

15 |

22 |

|

|

Drive Mode |

Motor Reducer |

Motor Reducer |

Motor Reducer |

Motor Reducer |

|

|

Crusher |

|||||

|

Device/Model |

CH430 |

HP300 |

HP400 |

HP300 |

|

|

Crusher Power(KW) |

132 |

220 |

315 |

220 |

|

|

Processing Capacity(t/h) |

150-200 |

110-440 |

135-630 |

110-440 |

|

|

Return Material Sieve |

|||||

|

Device/Model |

SX1536 |

SX1545 |

SX1545 |

SX1545 |

|

|

Number Of Screen Layers |

1 |

1 |

1 |

1 |

|

|

Belt Conveyor |

|||||

|

Main Belt Conveyor |

B1200 |

B1200 |

B1200 |

B1200 |

|

|

Side Belt Conveyor |

B1200 |

B1200 |

B1200 |

B1200 |

|

|

Material Return Belt Conveyor |

B500 |

B500 |

B500 |

B500 |

|

|

Drive Mode |

Motor Reducer |

Motor Reducer |

Motor Reducer |

Motor Reducer |

|

|

Machine Power(KW) |

184.4 |

293.4 |

388.4 |

293.4 |

|

|

Power System(KW) |

Cummins 330 |

Cummins 560 |

Cummins 560 |

Cummins 93 |

|

Attention:There are two types of crawler mobile crushing stations: pure electric drive and vehicle-mounted power drive. Please consult Shunzhi Machinery according to your needs.

ST Track-mounted Impact crusher

ST Track-mounted Impact crusher

ST series crawler type counter-attack breaking mobile station has an independent power unit and can walk independently.It has a complete feeding, crushing, screening, and return system.It can work alone or can be combined with jaw breaking,screening and other equipment to form a production line to meet the requirements of different customers.

|

Device/Model |

STF1010RS |

STF1214RS |

STF1315RS |

|

|

Feeding Department |

||||

|

Bin Volume(m³) |

4 |

6 |

6 |

|

|

Feeder Model |

FD1038 |

FD1248 |

FD1248 |

|

|

Feeder Power(KW) |

11 |

15 |

15 |

|

|

Maximum Feeding Particle Size(mm) |

500 |

750 |

750 |

|

|

Crusher |

||||

|

Device/Model |

SPL1010 |

SPL1214 |

SPL1315 |

|

|

Crusher Power(KW) |

160 |

250 |

315 |

|

|

Processing Capacity(t/h) |

80-200 |

100-400 |

150-500 |

|

|

Return Material Sieve |

||||

|

Device/Model |

SX1536 |

SX1545 |

SX1545 |

|

|

Number Of Screen Layers |

1(2) |

1(2) |

1(2) |

|

|

Belt Conveyor |

||||

|

Main Belt Conveyor |

B1000 |

B1200 |

B1200 |

|

|

Belt Conveyor Under Screen |

B1000 |

B1200 |

B1200 |

|

|

Material Return Belt Conveyor |

B500 |

B500 |

B500 |

|

|

Drive Mode |

Motor Reducer |

Motor Reducer |

Motor Reducer |

|

|

Machine Power(KW) |

215.4 |

317.4 |

382.4 |

|

|

Power System(KW) |

Cummins 330 |

Cummins 560 |

Cummins 560 |

|

Attention:There are two types of crawler mobile crushing stations: pure electric drive and vehicle-mounted power drive. Please consult Shunzhi Machinery according to your needs.

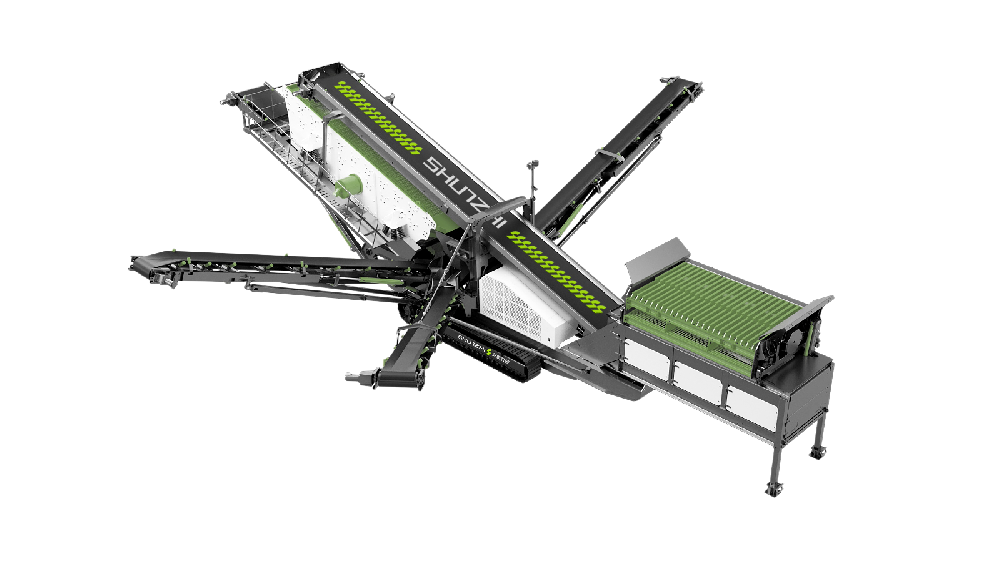

ST Track-mounted Vibrating screen

ST Track-mounted Vibrating screen

ST series crawler screening mobile station has an independent power unit and can walk independently. It can be combined with other crushing stations to form a production system. It is designed with a grate feed box and can work independently for pre-screening and other working conditions.

|

Device/Model |

STS1860-3 |

STS2160-3 |

STB1860-3 |

|

Feeding Department |

|||

|

Feed hopper volume(m³) |

3 |

3 |

8 |

|

Feed hopper form |

Ordinary style |

Ordinary style |

Rician style |

|

Screening machine |

|||

|

Device/Model |

3YK1860 |

3YK2160 |

3YK1860 |

|

Number of layers |

3 |

3 |

3 |

|

Belt Conveyor |

|||

|

Upper screen belt conveyor |

B1000 |

B1000 |

B1000 |

|

Belt Conveyor Under Screen |

B1000 |

B1000 |

B1000 |

|

Side Outlet Belt Conveyor |

650-6m |

650-6m |

650-6m |

|

Side Outlet Two-Belt Conveyor |

650-7.5m |

650-7.5m |

650-7.5m |

|

Side Outlet Three-Belt Conveyor |

650-7.5m |

650-7.5m |

650-7.5m |

Power |

|

Machine Power(KW) |

74.5 |

84.5 |

74.5 |

|

Power System(KW) |

Cummins 120 |

Cummins 120 |

Cummins 120 |

Attention:There are two types of crawler mobile crushing stations: pure electric drive and vehicle-mounted power drive. Please consult Shunzhi Machinery according to your needs.